Unmatched Expertise

With four decades of industry leadership, our unbeatable expertise ensures that your custom AGV or AMR solution benefits from the depth of our experience, guaranteeing exceptional performance and reliability.

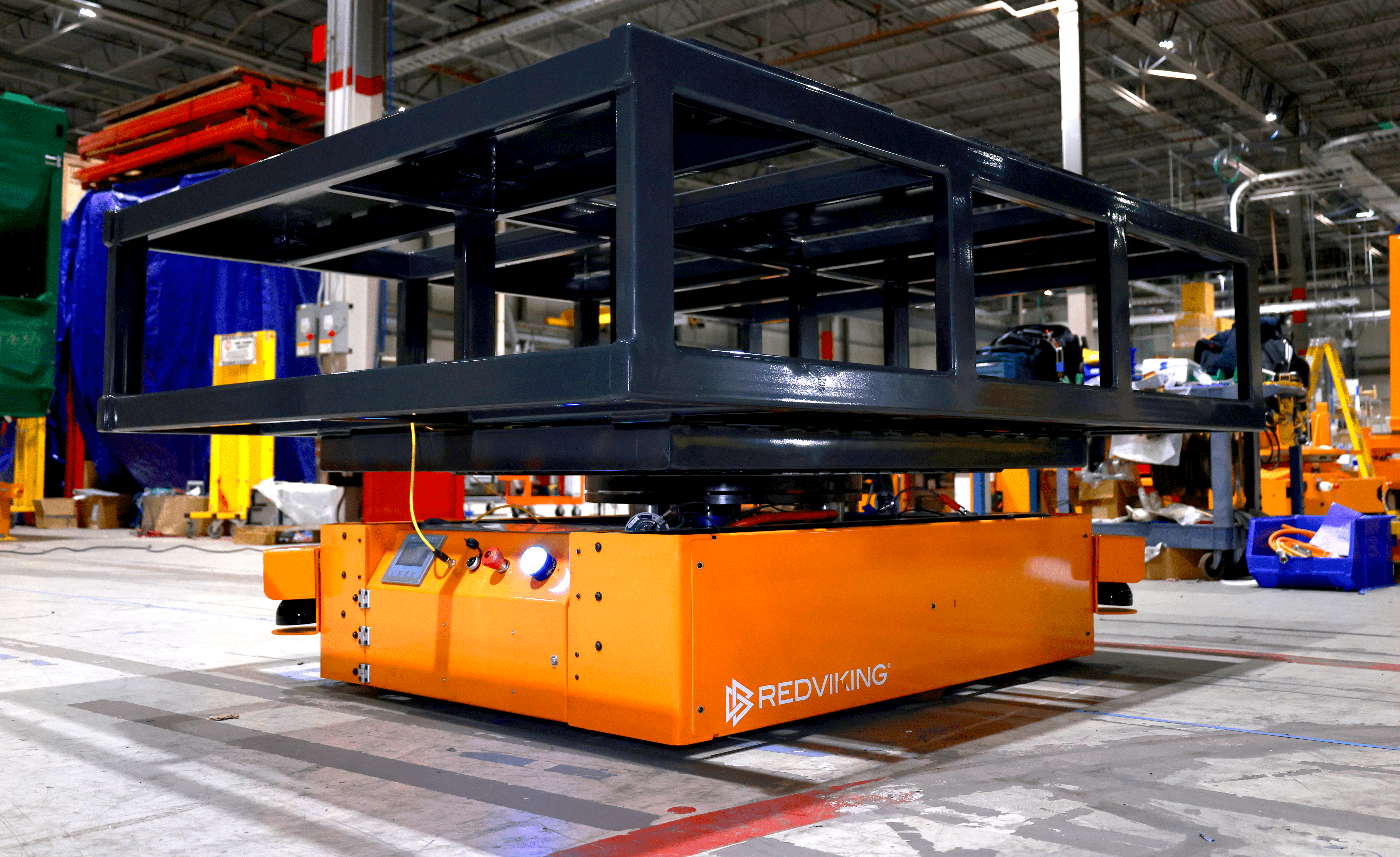

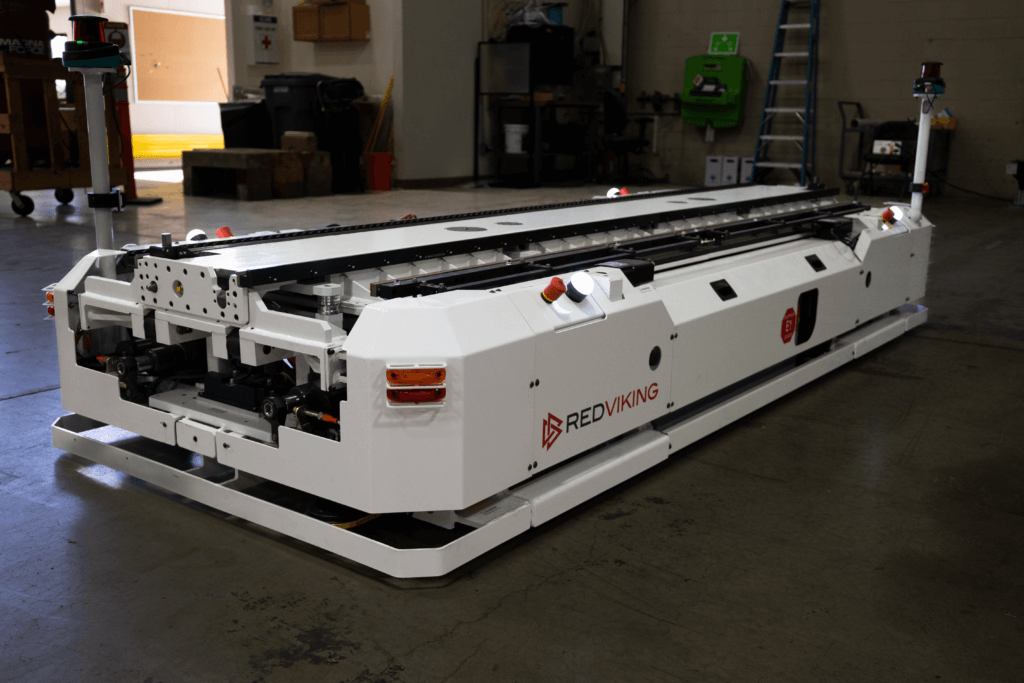

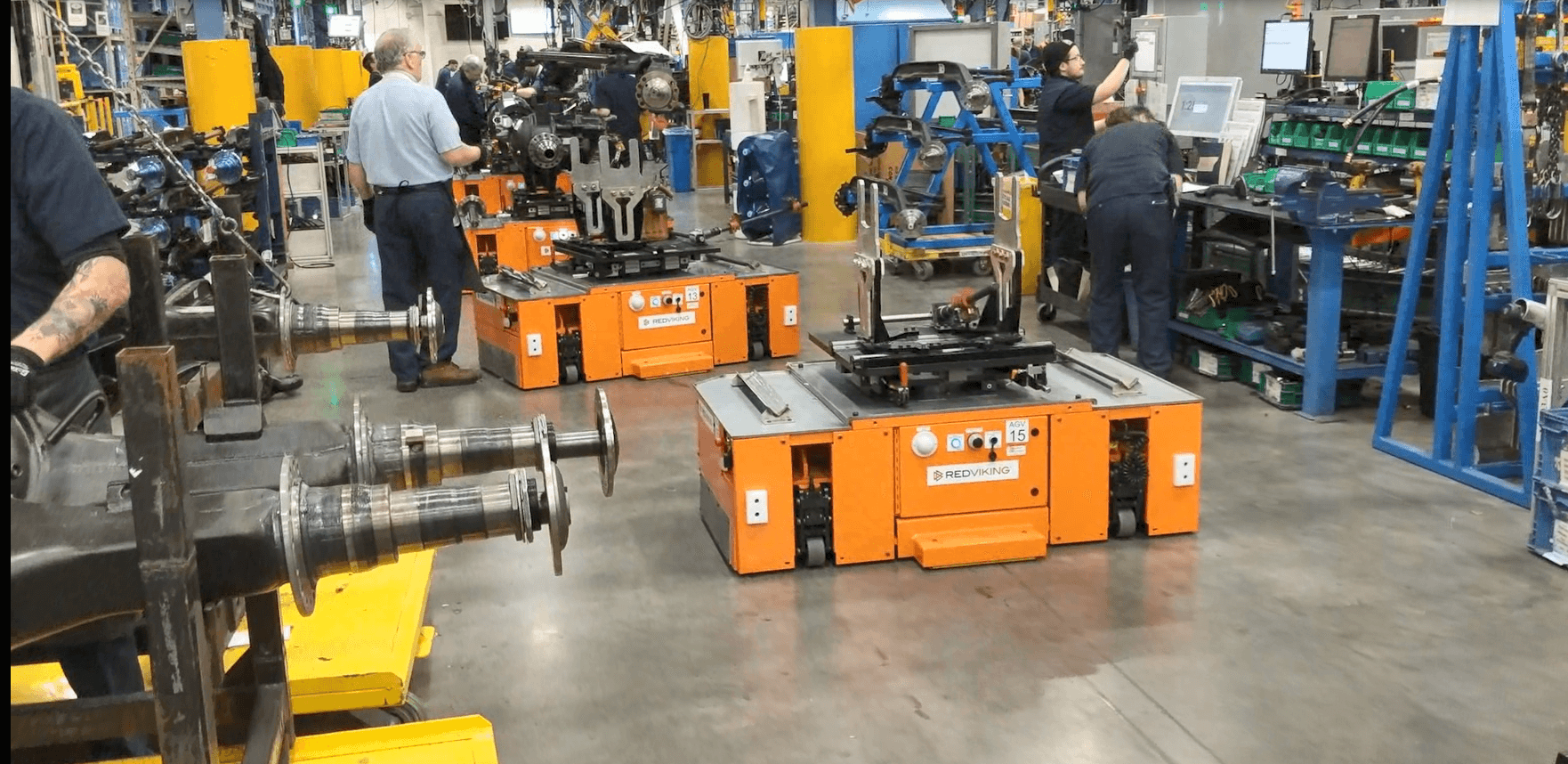

When your production needs are ultra-specific or complex, a custom automated guided vehicle (AGV) or autonomous mobile robot (AMR) can provide the flexibility and capability required for your operations. As the leading provider of custom AGVs and AMRs, we understand the importance of precision, efficiency, and reliability in your manufacturing, which is why we offer bespoke solutions meticulously crafted to address your unique challenges.

Our custom AGV or AMR solutions are centered around a consultative approach that encompasses the entire process, from brainstorming to execution. We collaborate closely with your team to understand the specific requirements, challenges, and goals of your manufacturing environment.

Solutions Aligned with Your Needs

Our design phase is not a one-size-fits-all endeavor. We tailor the design process to your requirements, considering factors such as load capacity, material flow, facility layout, and safety protocols. This personalized approach ensures that the resulting custom AGV or AMR aligns seamlessly with your production ecosystem.

Building Precision into Every Component

With decades of experience in automation, our engineering and manufacturing teams bring expertise to every build. Your custom AGV or AMR is constructed with precision and attention to detail, utilizing high-quality components to guarantee quality and longevity. Each component is carefully selected and integrated to meet the demands of your application.

Seamless Adoption into Your Workflow

Integration is a critical phase where theory transforms into reality. Our implementation team works diligently to integrate your custom AGV or AMR solution into your existing workflow. This involves seamless communication with other automation systems and your MES or FIS, ensuring a harmonious operation that enhances overall efficiency and productivity.

Nurturing Long-Term Success

Our commitment to your success doesn’t end with the integration of your AGV or AMR. RedViking provides ongoing support, maintenance, and optimization services to nurture the long-term success of your automation solution. Our responsive support team is ready to address any issues promptly, minimizing downtime and ensuring continuous, reliable performance.

With four decades of industry leadership, our unbeatable expertise ensures that your custom AGV or AMR solution benefits from the depth of our experience, guaranteeing exceptional performance and reliability.

Our dedication to innovation is evident through ongoing investment in research and development. We continually explore leading edge technologies, ensuring your custom AGV or AMR leverages the latest advancements for optimal efficiency.

From design to support, we offer comprehensive, end-to-end automation solutions. Beyond your custom AGV or AMR, we can support your production with our data and analytics, assembly line, and testing solutions.

Choose from various power sources, including battery options, Inductive Power Transfer (IPT®), and hybrid technology. Our team will help you identify the ideal power source to meet your specific AGV and AMR needs for optimal performance.

Engineered to adapt to your unique production processes and products, our AGVs or AMRs offer a versatile solution for a wide range of applications. We can build in a number of customization options to scale up or down, and utilize commercial off-the-shelf (COTS) components to streamline maintenance and maximize uptime.

Prioritizing your workforce and operations, our team is relentless in ensuring safety at every stage. Redviking adheres to all industry-standard safety regulations, including OSHA, ANSI, and NFPA guidelines. Our custom AGVs and AMRs adhere to rigorous design standards, incorporate collision avoidance technology, and provide continuous improvement to reduce workplace accidents and enhance ongoing safety.

Empower your production with our visionary automation solutions. Secure your place in the automated future – contact us to discuss your custom solution.