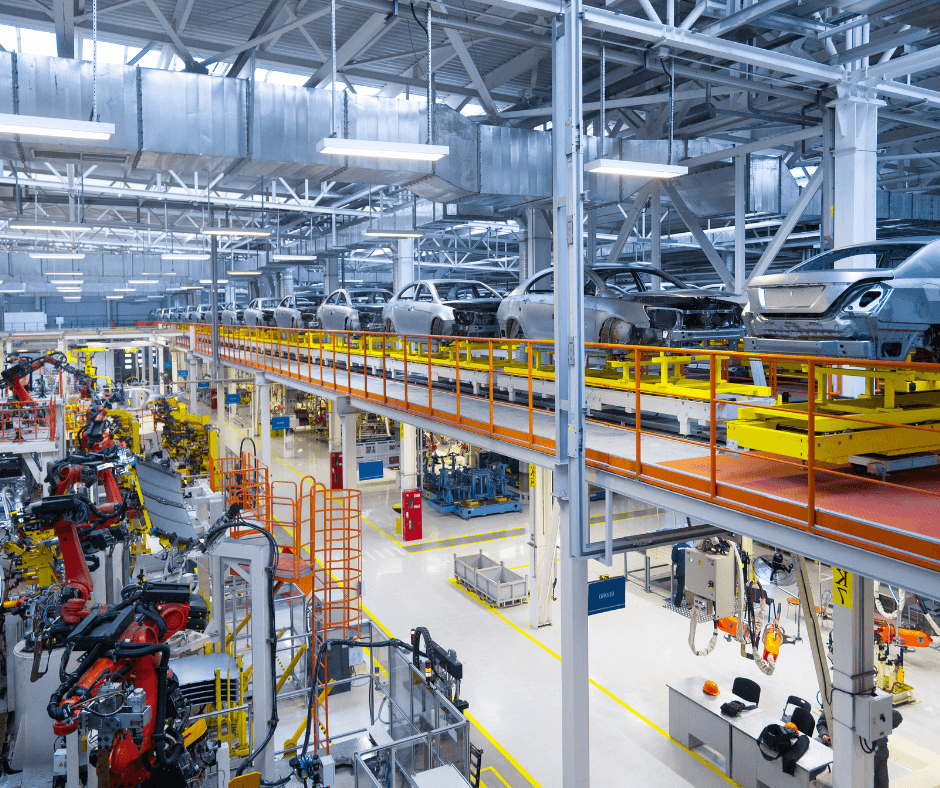

In response to the growing demand for sustainable transportation, a brand new state-of-the-art electric bus assembly plant was constructed in Illinois. This large medium to heavy-duty electric truck manufacturing company entrusted RedViking with designing and implementing a comprehensive conveyance system for the entire assembly process. The seamless integration of AGVs, specialized disembark station, and the visual display MES system collectively contributed to increased efficiency, control, and readiness for future growth.

Key Benefits:

- Multi-directional AGVs provide a high maneuverability

- Highly Flexible – fore/aft and cross car assembly line presentation – two AGV chassis system and large single bus body AGV, AGVs for axle build and cross member delivery

- Diverse payload and solutions

- 48,000 lbs across two Chassis AGVs

- 16,000 lbs single bus body AGV

- 3,500 lbs single or dual axle build AGV

- 1,500 lbs cross member tugger cart train AGV

- Guaranteed Uptime, unique travel paths, offline spurs, production hold spurs, inline charging, and continuous movement

- Fleet has shared components across AGV types and programming

- Universal RedViking engineering across all AGV systems

The multi-directional AGV for the bus body assembly spans an impressive 40 feet boasting precision tolerance while ensuring accuracy in the assembly process. RedViking’s commitment to precision was further exemplified by the design of the bus body AGV, which could be captured by both end and side work platforms. This allowed operators to enter directly into the EV Bus assembly directly on top of the AGV.

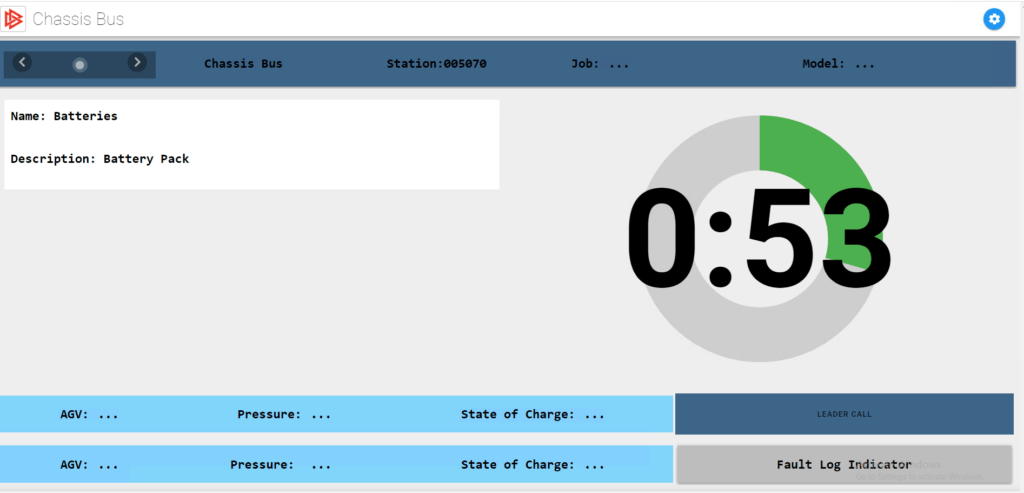

The incorporation of a dual AGV system for the chassis assembly, capable of operating in both front and rear positions, added an extra layer of flexibility to the assembly line. The AGVs can accommodate an array of bus lengths by being called to discrete locations by VIN. Operators are not restricted in access with a clear span from front to rear AGV. AGVs communicate and manage multi-directional movements and non-traditional travel paths through drive pod capabilities. The continuously moving assembly system, coupled with battery opportunity charging in the chassis turns, ensured a seamless and uninterrupted workflow.

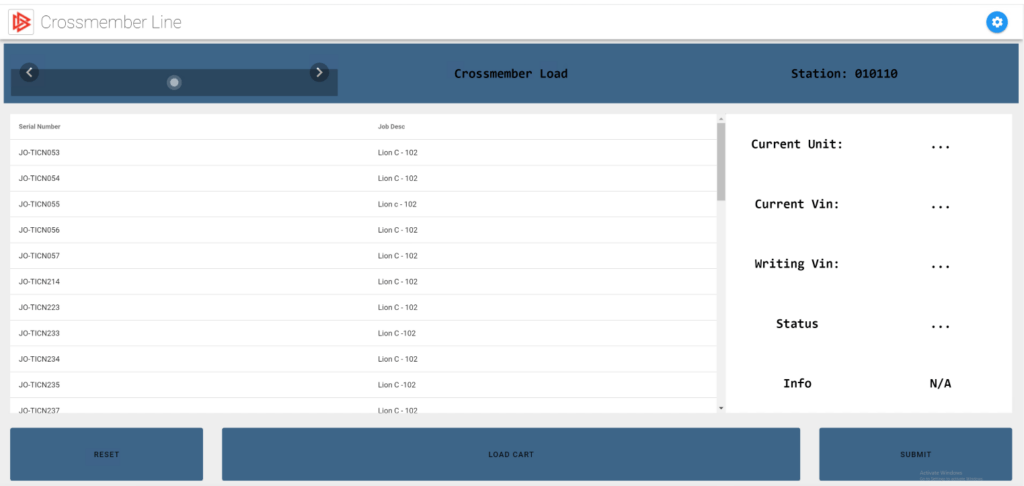

Leveraging its experience from past class VIII truck projects, RedViking implemented a standard cross-member material delivery AGV and a reimagined axle build AGV accommodating EV axle assembly.

This AGV system was complimented by FIS and MES display managers powered by Argonaut:

The Argonaut system provides a common system to track carrier movement and visualize production workflow, monitor and control production performance via ANDON, common metrics and dashboards, and provide a base for implementing operator work instructions and error proofing.

The RedViking Argonaut MES System includes the following:

- Argonaut FIS Data for Manufacturing Monitoring

- Argonaut Tracking Application for Production Tracking and Visualization

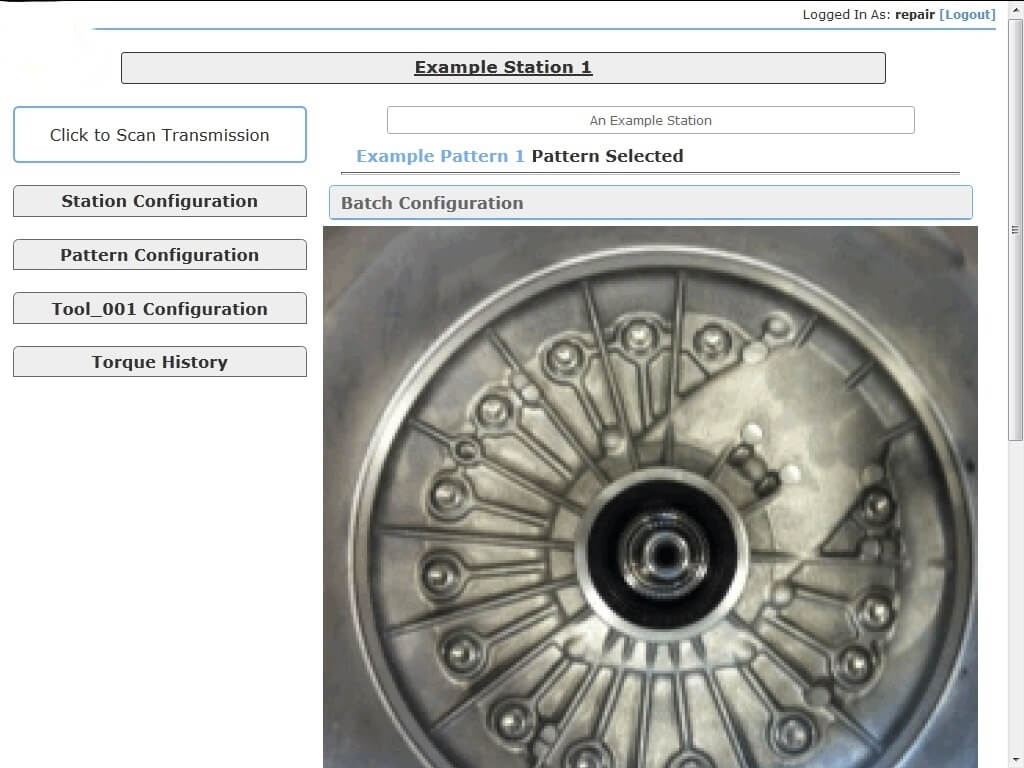

- Directed Manufacturing (Error Proofing) Application

- Large Screen ANDON display boards for on-the-floor visualization

- System Integration and implementation engineering services

RedViking faced a multifaceted challenge in launching multiple Automated Guided Vehicle (AGV) lines within a demanding timeline. The complexity was exacerbated by the co-creation and partnership of creating system performance and capabilities with emerging process information and real-time release of product design for expedited launch. System requirements required flexibility and gateways to handle up to 40 different future bus models undergoing emerging data and model changes. RedViking worked closely with the customer to ensure their world-class factory vision came to life with a dynamic and adaptable solution.