RedViking is a certified integrator of Inductive Automation’s Ignition® system. With systems deployed in diverse industries including Automotive, Renewable Energies, and Logistics, RedViking supports the launch, expansion, and rollout of advanced solutions. Our team works closely with our customers, collaborating on specifications and initial design through to the project execution, initial installation, and scale-out phases.

Partner with RedViking on your next Ignition project and realize the value of working with a systems integration partner with over 30 years of turnkey systems integration experience.

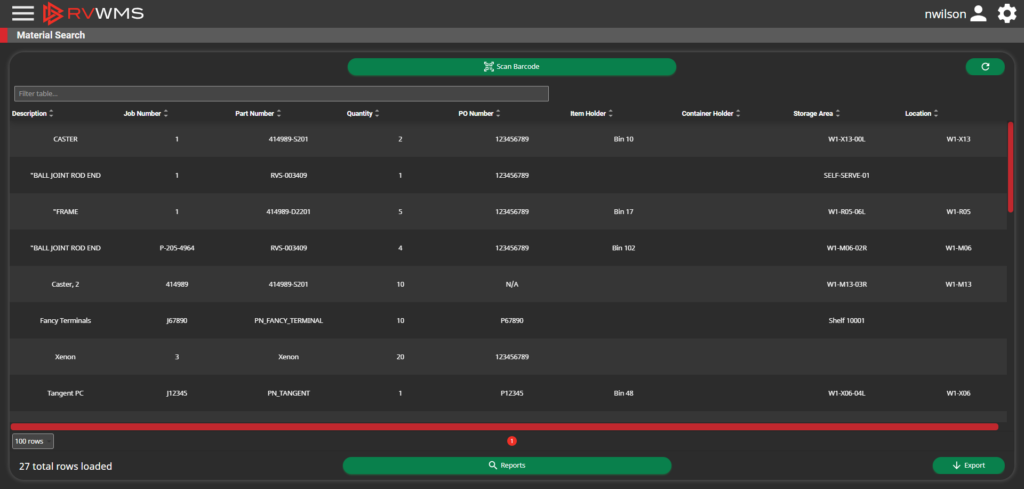

RedViking’s Warehouse Management Solution (RVWMS) is used to ease logistics operations for custom solution manufacturing customers. Our unique solution provides a critical link between ERP and operations allowing material to be efficiently tracked upon being received, efficiently kitted and picked to meet a flexible and dynamic production environment, and provides visualization to the entire organization on material movements and status.

RedViking integrates our AGV and AMR fleets with Ignition to

provide real-time feedback of system status, provide a common interface for pick-and-drop

requests, and visualize system metrics.

Using an Ignition-based interface provides a common

interface for our customers which often integrates with existing solutions and

eases the integration of related equipment and processes.

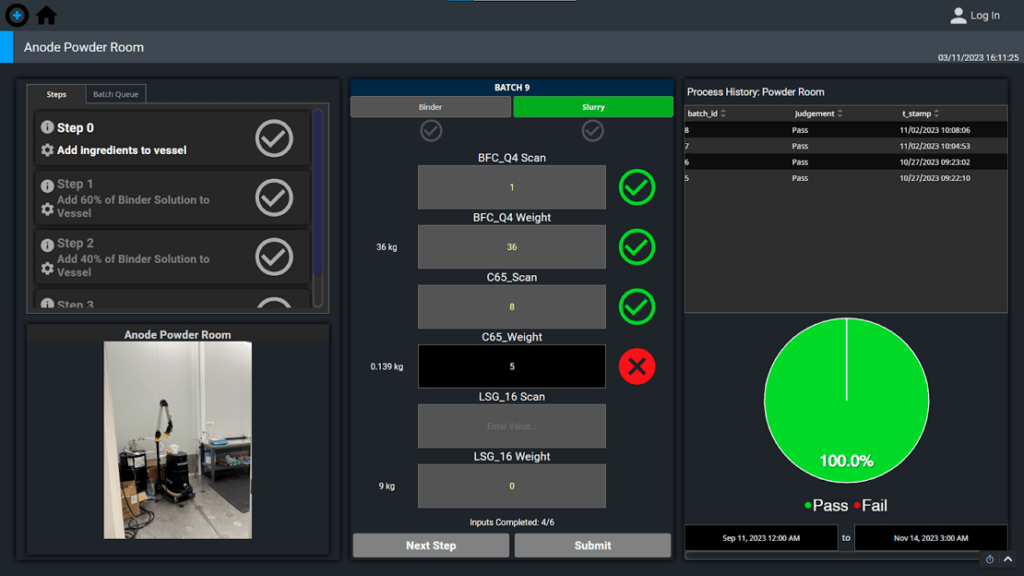

Integration of a new battery cell assembly line with advanced features such as data collection and full traceability across serialized products. This includes monitoring through IPQC, SPC, and critical data collection, as well as ensuring traceability at every stage before product advancement. The system also manages recipe changes, barcode labeling, production scheduling, and integrates with Microsoft Dynamics for scheduling. Furthermore, it generates comprehensive reports including traceability by serial number, gate check results, process data, machine faults, OEE, and daily shift reports distributed via email.

A new powertrain assembly line has been integrated with full traceability for serialized parts and data collection. It generates serial numbers for parts at the process start and allows users to create and edit recipes. The system tracks part numbers and stations in real-time, collects specific assembly parameter data, and performs gate-checks when marrying parts. Additionally, it accommodates reintroduced or reworked parts, supports multiple models, and provides historical reporting features.

RedViking’s Pick-To-Light application is utilized in logistics and manufacturing settings to streamline operations. The system is used to drive sensors, read barcodes, and display work instructions. Light indicators guide operators to select the correct parts and quantities efficiently. Error-proofing features ensure accuracy by validating part selection, with easy configuration for adding new items. Built-in reporting tracks operator performance and kit assembly times, with fail-safes in place for detecting multiple errors in picking.

Integration at a heavy equipment manufacturing plant capable of data collection and vehicle location. The system is configured to read in a barcode scan at the start of the manufacturing process (from a paper traveler) and marry a vehicle VIN to a specific AGV. As the AGV moves through the production process (mainline and sub-assembly lines), FIS data (states, counts, cycle times, faults) is collected as well as open concerns on the vehicle. Interlocks between the plant floor AGV controls and Cummlocity are in place to pass clear to release and open concerns. Large displays are strategically located on the plant floor to display real-time data. The system can also be viewed with cell phones, tablets, and computers. Color and graphics are used to represent status and locations.

RedViking’s software engineering team creates and supports Ignition modules that extend the platform’s native capabilities. Our combined experience with automation and systems integration provides insight into where modules fit and how to implement them.

These modules provide rapid and supportable implementation of today’s leading IIoT-based solutions, while minimizing risk with pre-built and supported integrations.

Supporting Navithor AMR Fleet integration, this module expands the Ignition API and provides out-of-the-box UI components providing instant integration with Navitec’s modern AGV Fleet Management solution. More details on the API and specifics are available on our module-specific mini-site.

RedViking partners with PDI Digital to deploy Electronic Label solutions in manufacturing. Our solutions range from straightforward shelf label solutions to more intricate systems involving automated integration with ERP and scheduling systems to complete:

Dynamic Build Sheets

Kit Tracking Sheets

Kit Pick-to-Light and Put-to-Light System

Our integration expertise with PDI digital and Ignition allows for rapid integration of the new label technology where an existing Ignition system is in place, providing an interface to existing infrastructure.

Quuppa provides a Real-Time RTLS API solution based on Bluetooth Low Energy (BLE) Angle of Arrival (AOA) which is a perfect solution for tracking 100s to 1000s of devices, people, equipment, and objects as well as integrating wireless sensing technology.

RedViking’s Quuppa integration speeds time-to-delivery for advanced tracking applications in industry.

Empower your production with our visionary automation solutions. Secure your place in the automated future – contact us to discuss your custom solution.