Optional Navigation Options

Choose from Line Following or Virtual Line Following Navigation Systems:

- IPT

- Tape Following

- LiDAR with Reflectors

- LiDAR with Natural Feature

- Vision Based

As early pioneers in AGV and AMR technology, we’ve poured 40 years of engineering know-how into developing a standardized product that delivers high performance, long-term sustainability, and exceptional flexibility. Our FlexForm AGV and AMR solutions come with custom tooling options to build a solution that works seamlessly in a diverse array of applications and environments.

Designed with open controls architecture, our FlexForm AGVs and AMRs use commercial-off-the-shelf (COTS) components to make service and maintenance seamless, ensuring maximum uptime.

Our standard, customizable AGV offers flexibility for various applications, ensuring adaptability to specific manufacturing needs while maintaining seamless integration within your production environment.

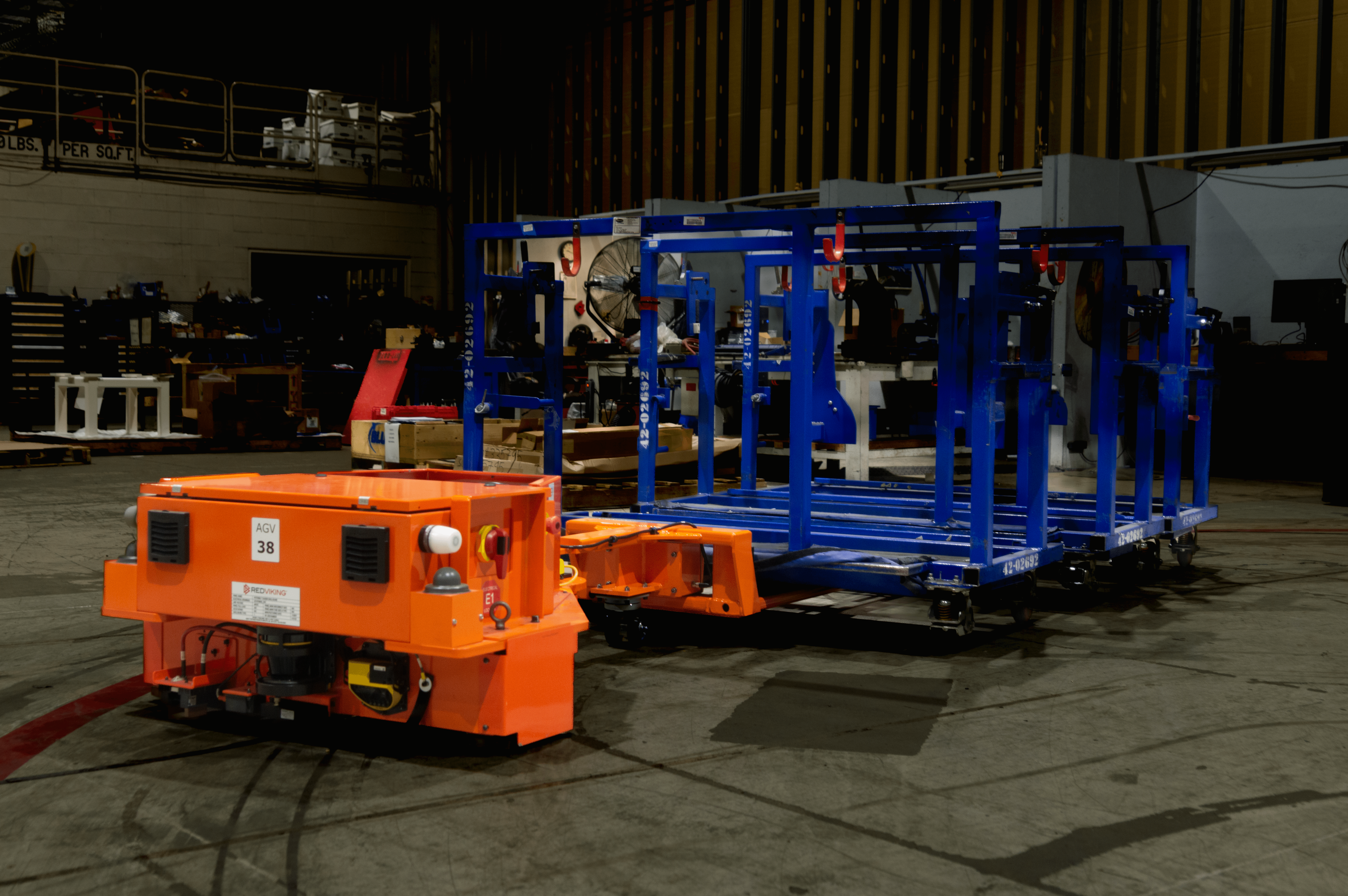

Efficiently transport materials with our Tugger AGV, enhancing productivity by autonomously towing carts throughout your facility, optimizing material flow and minimizing manual handling.

Navigate through tight spaces effortlessly with our Tunneling AGV, designed to maneuver in confined areas while delivering precision and reliability, even in challenging manufacturing environments.

Streamline material transport with our Chassis AGV, providing a robust and versatile solution to effortlessly move heavy loads, improving efficiency and optimizing workflow in your manufacturing facility.

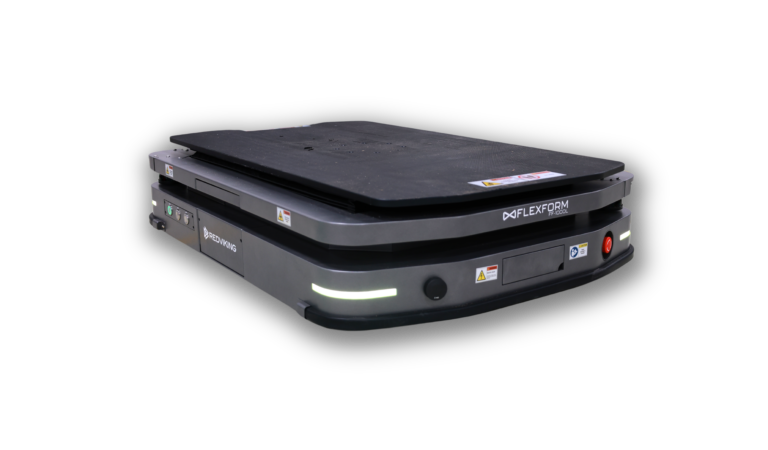

The FF-300B AMR is a Mobile Robot Chassis that is a versatile and adaptable platform tailored for a wide range of mobile robot applications. The FF-300B chassis is engineered to accommodate additional components such as rollers, lifting mechanisms, and collaborative robots (cobots), enabling users to customize their robotic systems according to specific needs.

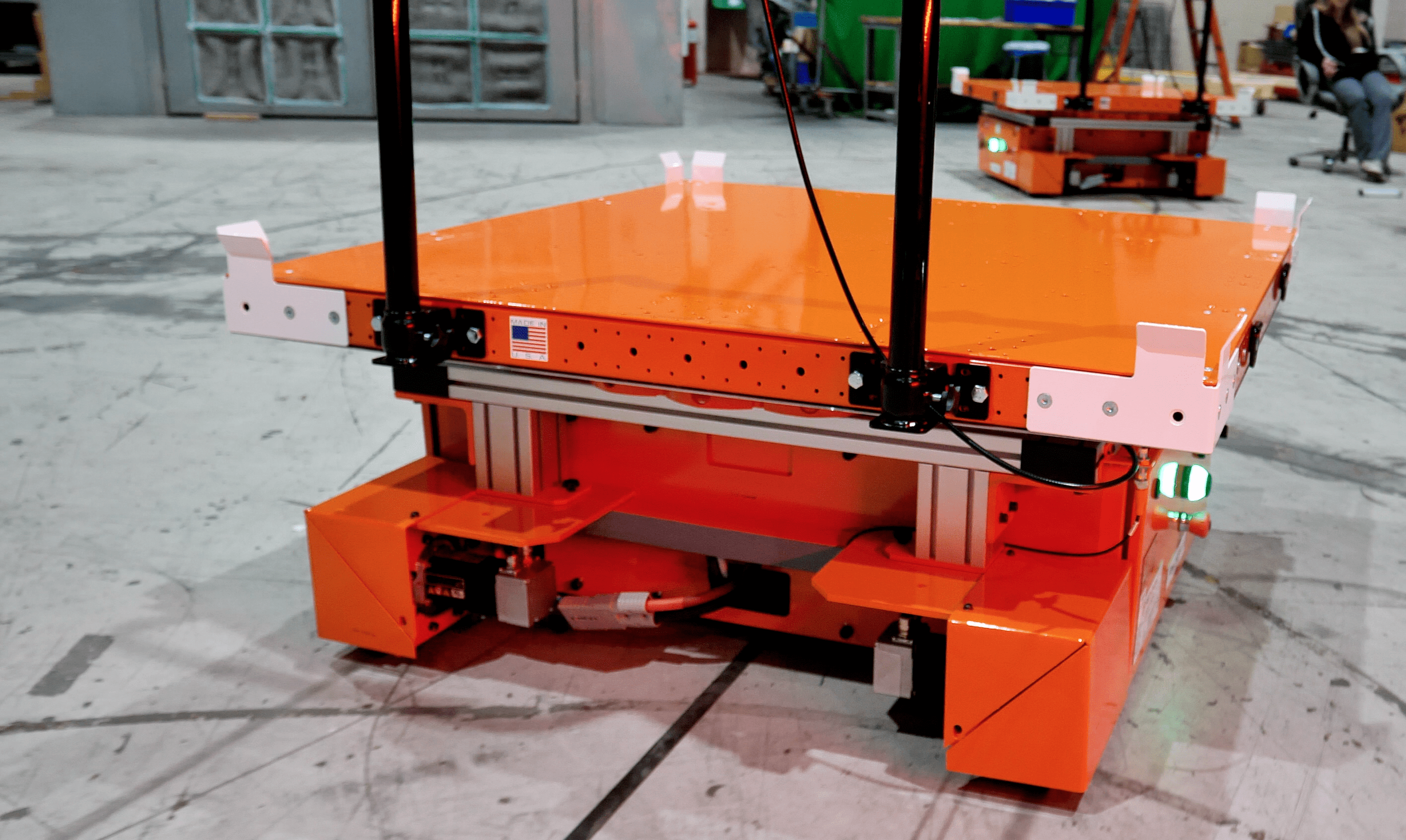

The FF-1000L AMR Laser SLAM Lifting Robot is a high-capacity robotic solution designed for safe and efficient transportation of heavy loads, lifting up to over 2,000 pounds (1000 kg) with a 60 mm range. Utilizing advanced Laser SLAM technology, it ensures precise navigation for accurate movement in factory and warehouse logistics. This robot streamlines operations, automating the transportation of shelving units and goods, enhancing productivity and safety in industrial settings.

The FF-500LS AMR is a cutting-edge Laser SLAM Lift and Spin Transfer Robot designed for the seamless movement of shelving and racks of goods weighing up to 1,000 pounds (500 kg) Leveraging advanced Laser SLAM technology, this robot ensures precise navigation, allowing for efficient and accurate transfers in various environments. With its unique lift and spin capabilities, the FF-500LS enhances logistics operations by automating the handling of heavy loads, providing a versatile solution for warehouses and industrial settings.

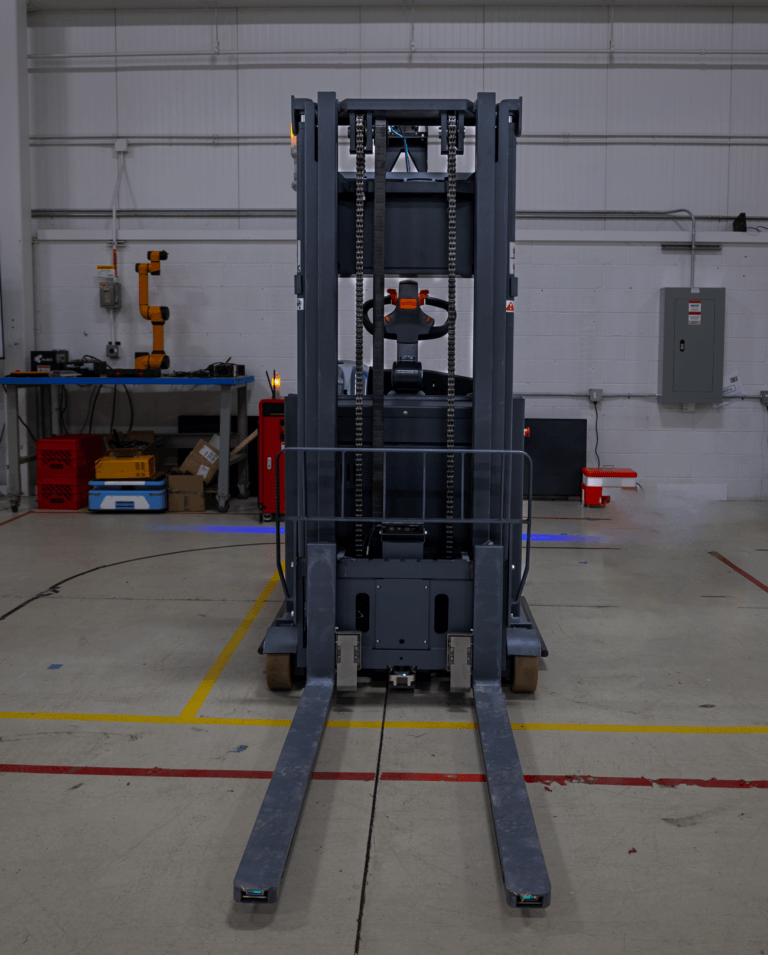

The FF-1500CFL is an innovative warehouse forklift designed for seamless deployment in logistics and warehouse environments that can transfer goods just over 3,000 lbs (1500 kg). Featuring Laser SLAM navigation, this robot ensures efficient and accurate movement for tasks such as moving, stacking, and palletizing goods. Equipped with an identification sensor, the FF-1500CFL can precisely pick up pallets, providing a versatile and reliable solution for optimizing operations in factories and warehouses.

Our custom tooling options enable you to start from a standard base, then build an AGV or AMR that fits your requirements. Configure your AGV or AMR to your application, enabling multi-part variations on the line and maximum operator accessibility to the part.

Choosing the leader in AGV and AMR manufacturing has its advantages. Our engineering consultants provide hands-on guidance to build a robotic solution that suits your needs.

Choose from Line Following or Virtual Line Following Navigation Systems:

Engineered to adapt to your unique production processes and products, our AGVs or AMRs offer a versatile solution for a wide range of applications. Enjoy a lower entry cost as our system eliminates the need for additional infrastructure, ensuring a tailored approach to your specific application.

Reconfigure equipment rapidly and cost-effectively to accommodate changes in product, process, or path. Easily add AGVs or AMRs as needed, adapting to line changes or increasing production rates for enhanced flexibility and cost savings.

Equipped with advanced navigation technology, FlexForm AGVs and AMRs prevent collisions and identify obstacles. 360-degree access, lift, and articulation enhance operator ergonomics, reducing the risk of worker injury.

Our AGVs and AMRs integrate with your existing MES or FIS so you can easily access data about position, movement, charging levels, and diagnostics. Our team can further optimize data collection through our Argonaut® manufacturing software solution.

Empower your production with our visionary automation solutions. Secure your place in the automated future – contact us to discuss your custom solution.