- Verification of gear quality through quality documentation

- Establish gearbox assembly procedures

- Perform gearbox dynamic validation and performance analysis

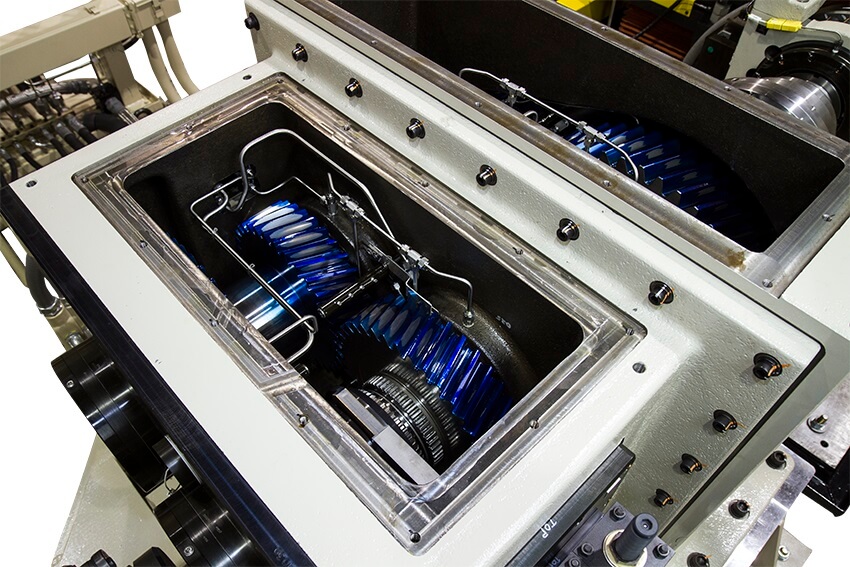

RedViking has developed gearboxes for some of the world’s most demanding customers, including NASA and the United States DOD. All gearboxes are developed using a rigorous, specific procedure to ensure accuracy, durability, and consistency. Our customers rely on the precision and reliability that RedViking gearboxes provide.

Before any gearbox can be shipped to a customer, an Acceptance Testing Plan is established, and the complete parameters of this plan must be met. Usually, equipment performance criteria determine the elements of the Acceptance Plan. It’s important that the gearbox performance is such that it does not have any negative influence on the overall machine performance. If the gearbox design steps above are carefully followed, this is sure to be the case.

Empower your production with our visionary automation solutions. Secure your place in the automated future – contact us to discuss your custom solution.