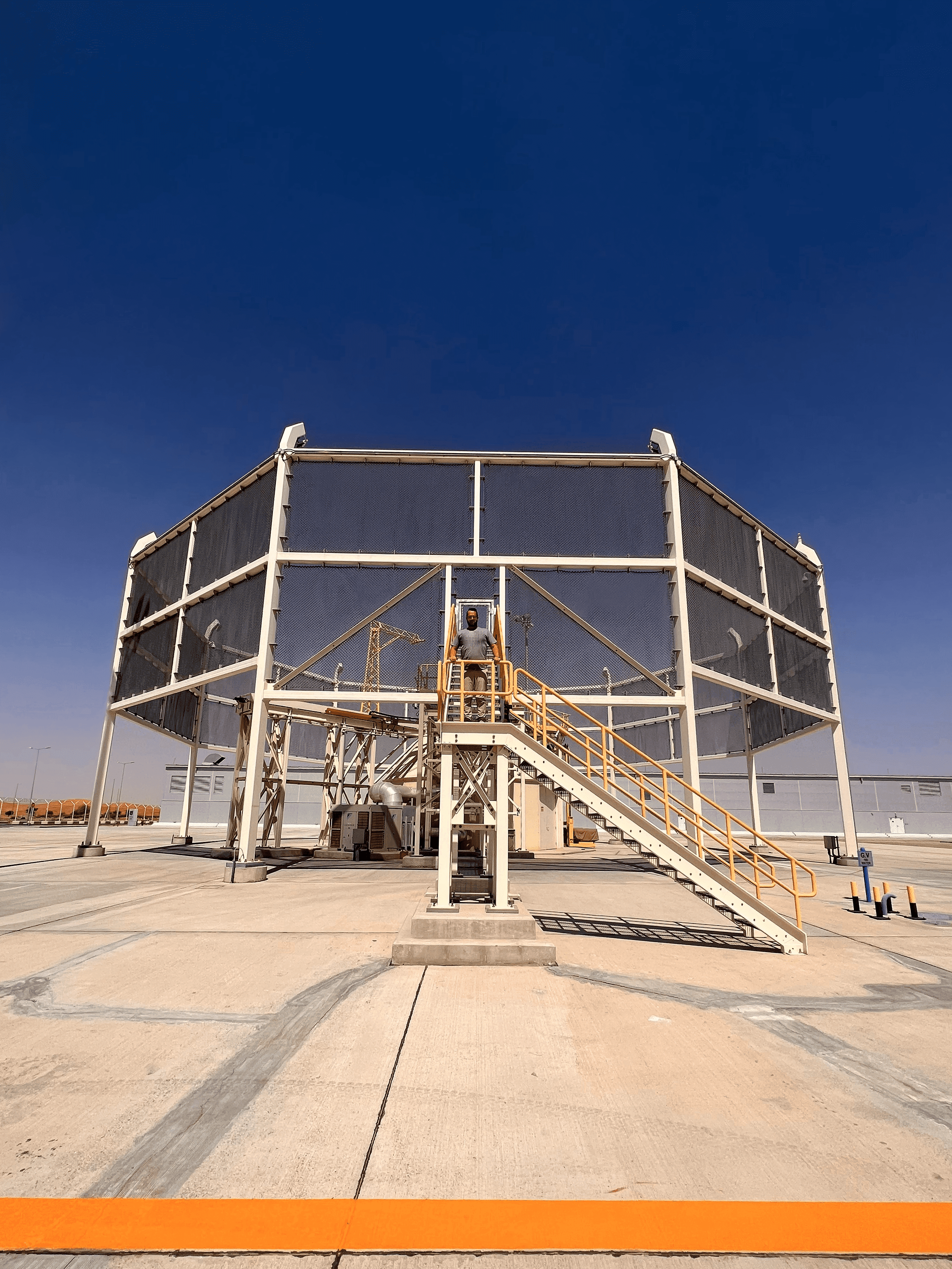

Flexible Testing

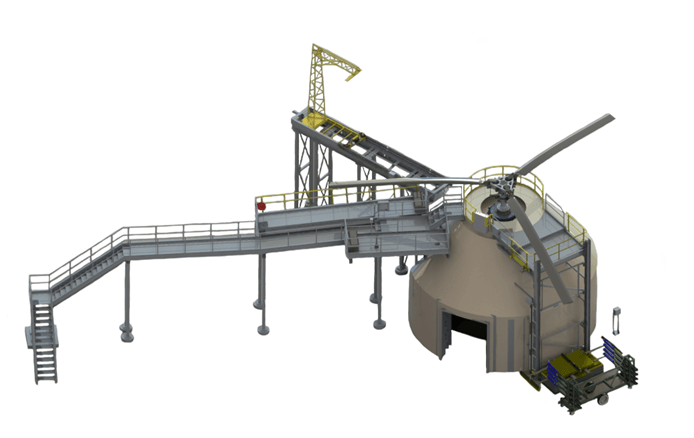

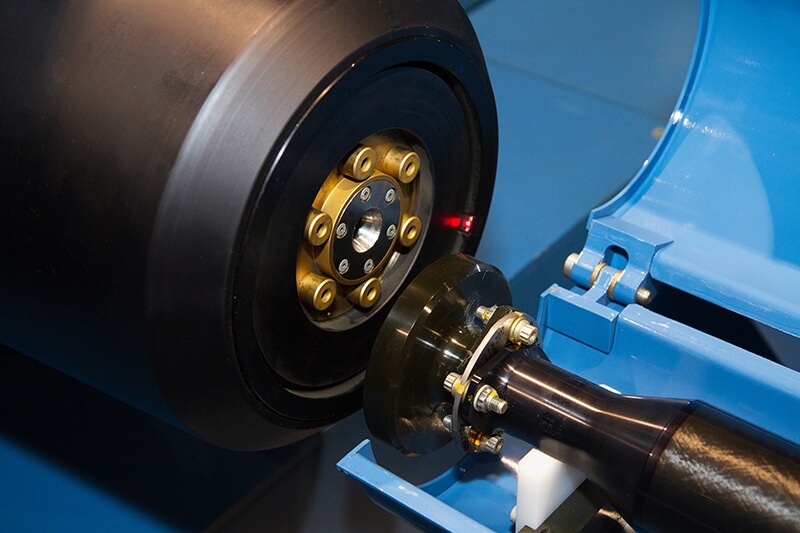

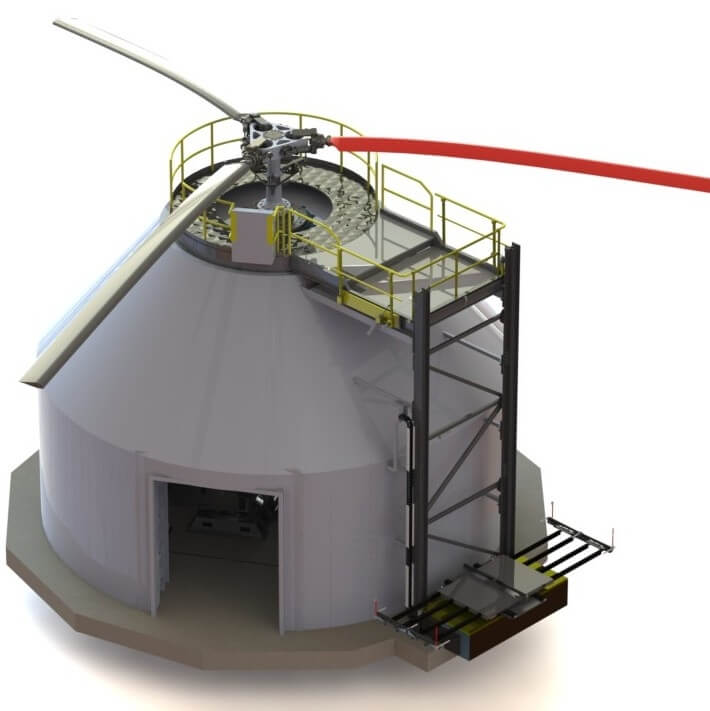

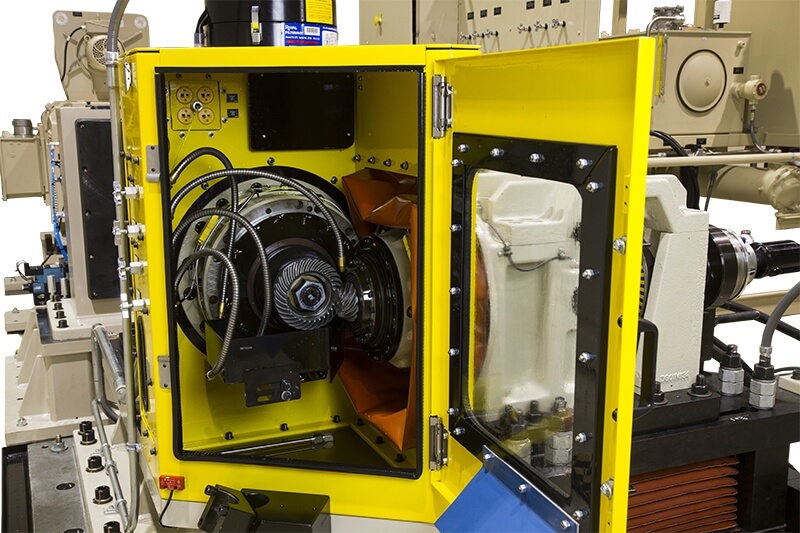

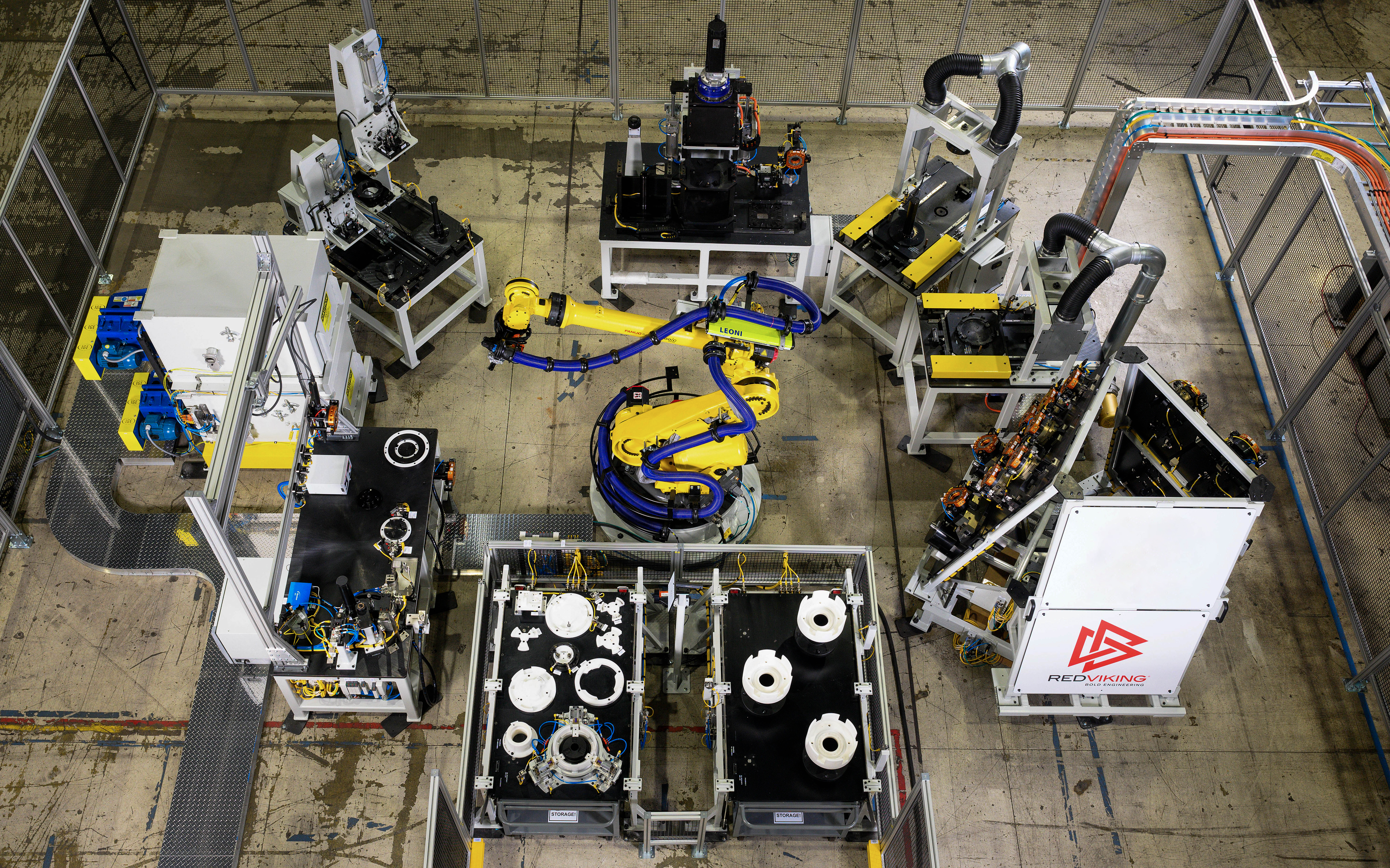

As specialists in flexible systems, we’ve developed an extensive range of rotary balancing capabilities to handle current and future requirements. With the ability to adapt to various rotor heads, blade connections and blade lengths, RedViking dynamic blade balance stands are capable of testing rotor blades from multiple aircraft and OEMs on a single tower. RedViking has provided systems with drivelines capable of nearly 6000HP continuous duty, generating speeds up to 400rpm with operation in either direction.