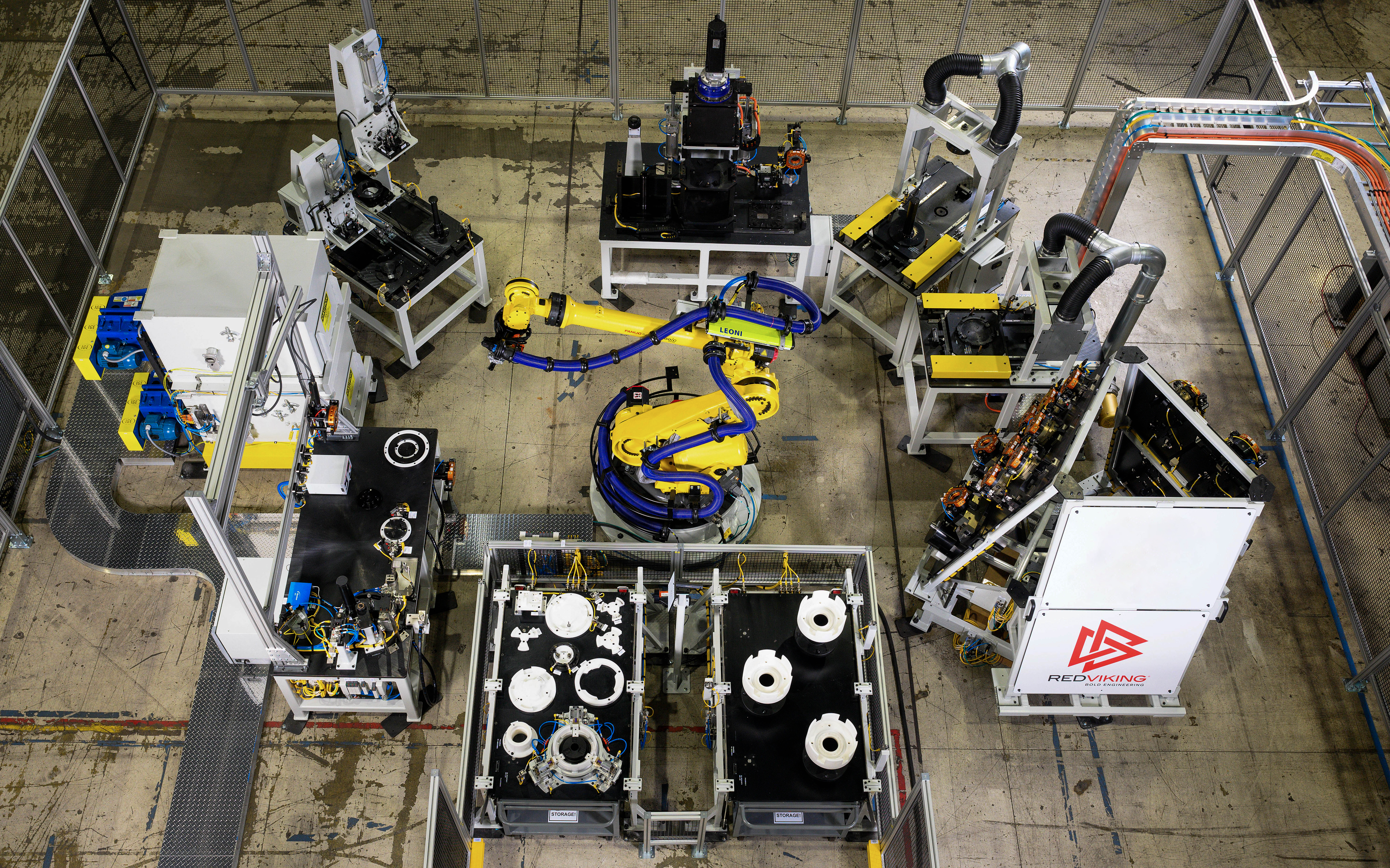

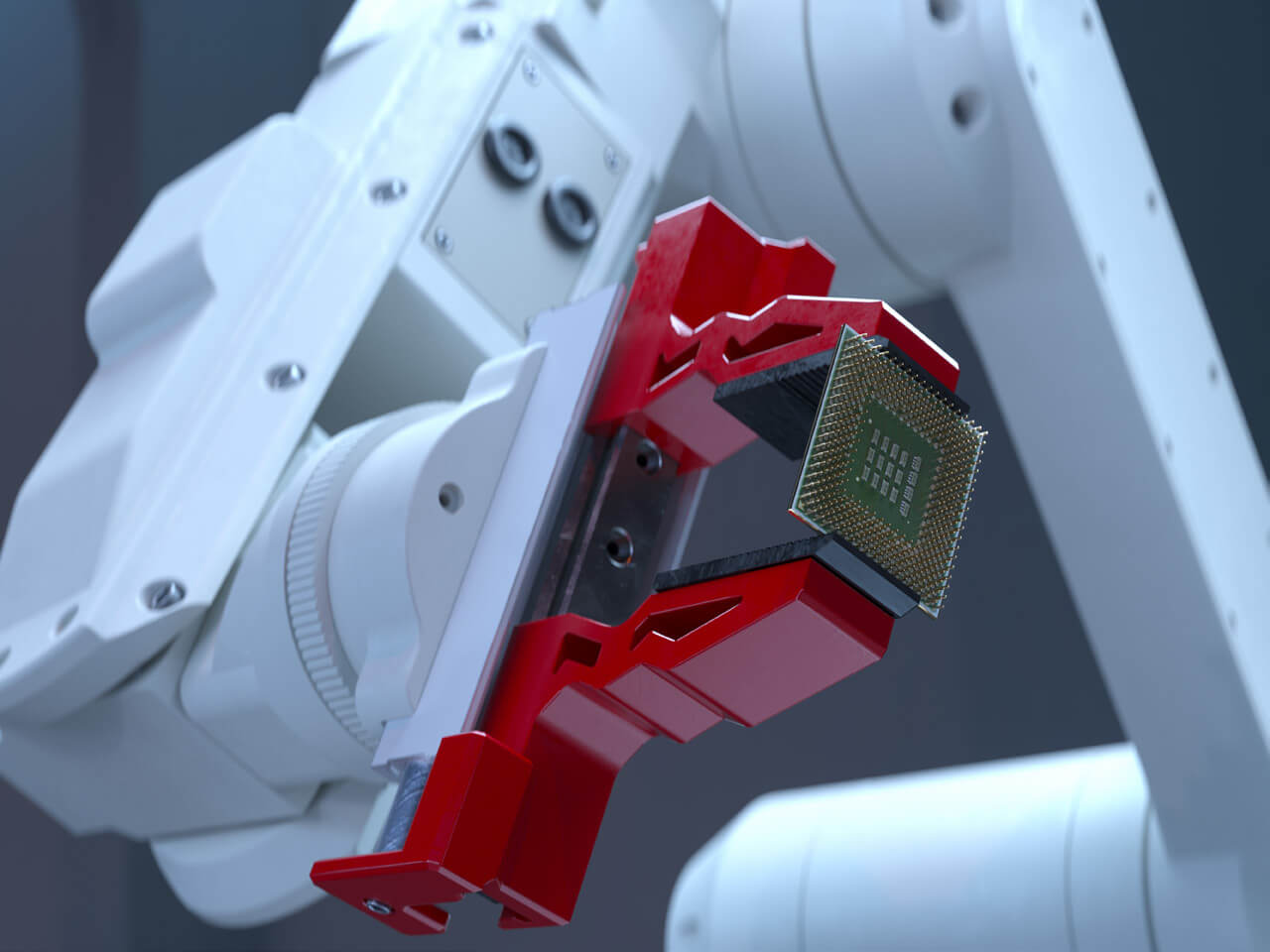

Automate Assembly Processes Where Previously Incapable

Robotic integration on assembly lines and in production cells allows manufacturers to operate at maximum efficiency. With new technologies in motion control, vision guidance and zone protection, robots can now gently load and unload parts, trim metal parts, weld parts together, and various other repetitive tasks in industrial manufacturing facilities. RedViking, an experienced integrator with over 30 years’ experience will study your processes, design a unique solution to your challenge and maximize your operation efficiency with robotic integration.