RedViking’s MES/FIS Helps You Stay One Step Ahead

One of the world’s largest automotive manufacturers needed to anticipate and prevent assembly line bottlenecks and equipment breakdowns. They turned to RedViking’s expert manufacturing execution systems team to offer a solution. We designed, implemented and supported an OEE/Factory Information System equipment health monitoring system with process diagnostics and analysis, integrated with a third-party maintenance notification system.

Key Benefits:

- Significantly Improved Line Efficiency

- Maintenance Downtime Minimized

- Elimination of Bottlenecks Before They Occur

- Maintenance Based on Real Factory History Data, Not Vendor Recommendations

- Line Interruptions Communicated Via Pager to the Right Person for Specific Machine or Tool

- Management Can View Real-Time Plant Activity From Any Authorized Device

Stop Production Problems Before They Start

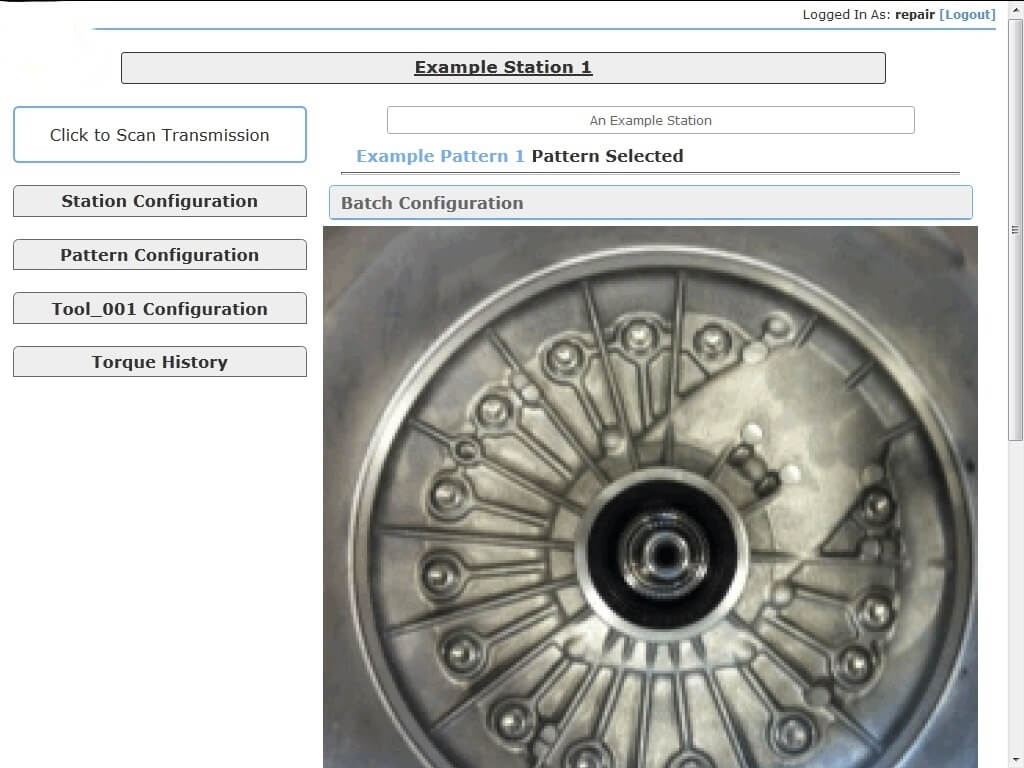

One of our customer’s primary goals was to anticipate and prevent bottlenecks, quickly identify the root source for downtime, and design their maintenance schedules to prevent equipment failure. RedViking implemented a complete OEE/Factory Information System to acquire raw manufacturing data and convert it into usable information to help them reach their goals.

Big Data From Plant Floor for Better Production

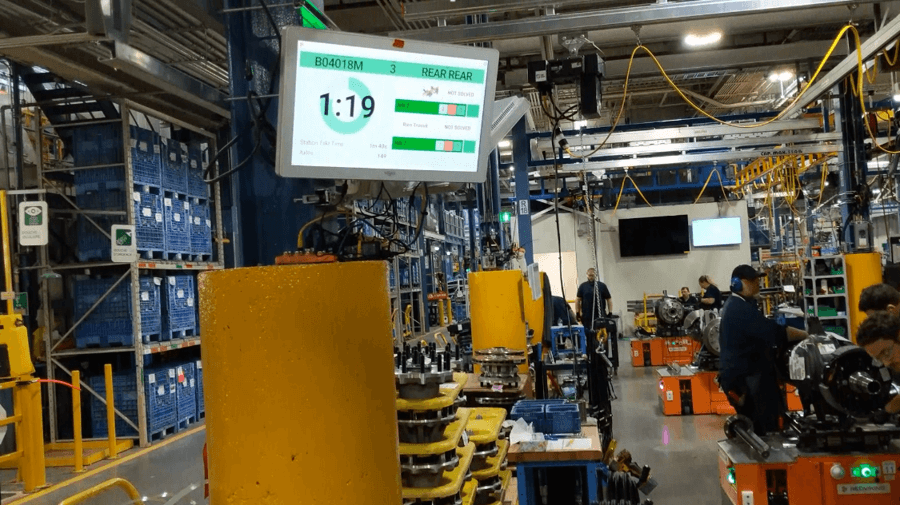

Machine and process data is collected from each production station and sent to an on-premise host server database. Our capabilities now allow this to be cloud-hosted by an Argonaut platform. Once captured, data can be posted overhead on an Andon board, sent via pager to a specific maintenance person, included in a management report, or redirected in virtually any secure configuration. In this case, a third party maintenance notification system was integrated to track maintenance response times. RedViking’s OEE/FIS provides extensive manufacturing analytics for process improvement, and can easily integrate third-party systems.

Maintenance Decisions Based on Unique Data

Equipment reliability data is collected so that preventative maintenance can be scheduled before tools and parts need to be replaced. By creating a maintenance schedule based on unique historical data from every part and process instead of data supplied by their equipment vendors, they maximize equipment health and minimize downtime and equipment failures.

If a particular machine is less reliable than one supplied by a different vendor, they have the data to select vendors accordingly. The same is true of parts. Quality managers will know which supplier’s badges are more effective.

Big Data for Better Process Management

The bottom line for the equipment and process monitoring system is improved efficiency. Instead of reacting to equipment failure and line bottlenecks, this automaker now has the data to prevent them through a complete understanding of their own equipment health, life, part quality, process variations, and production flow.