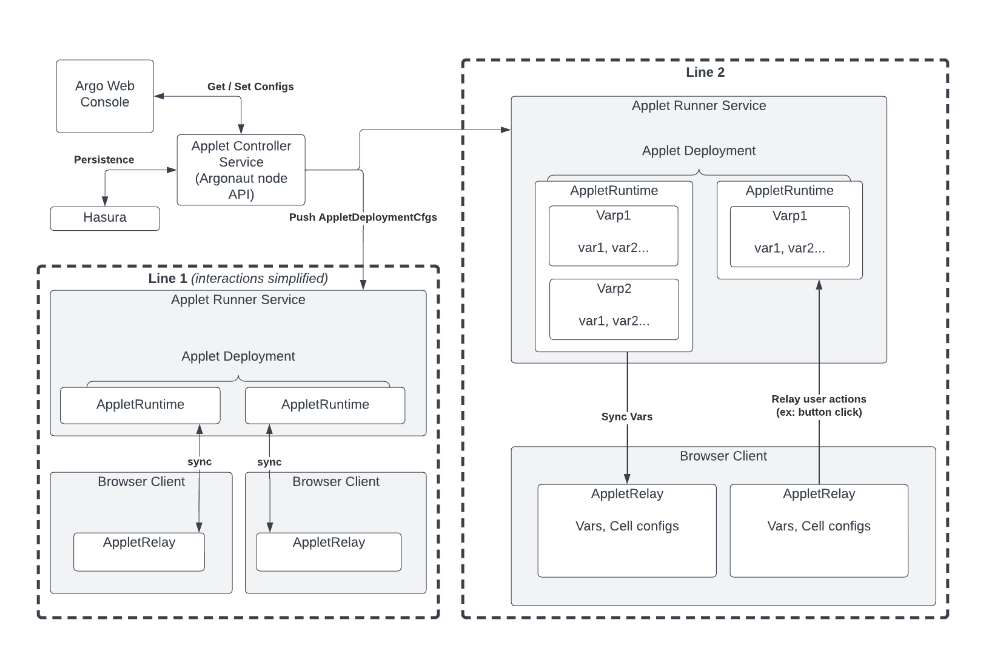

Applet Runners and Runtimes

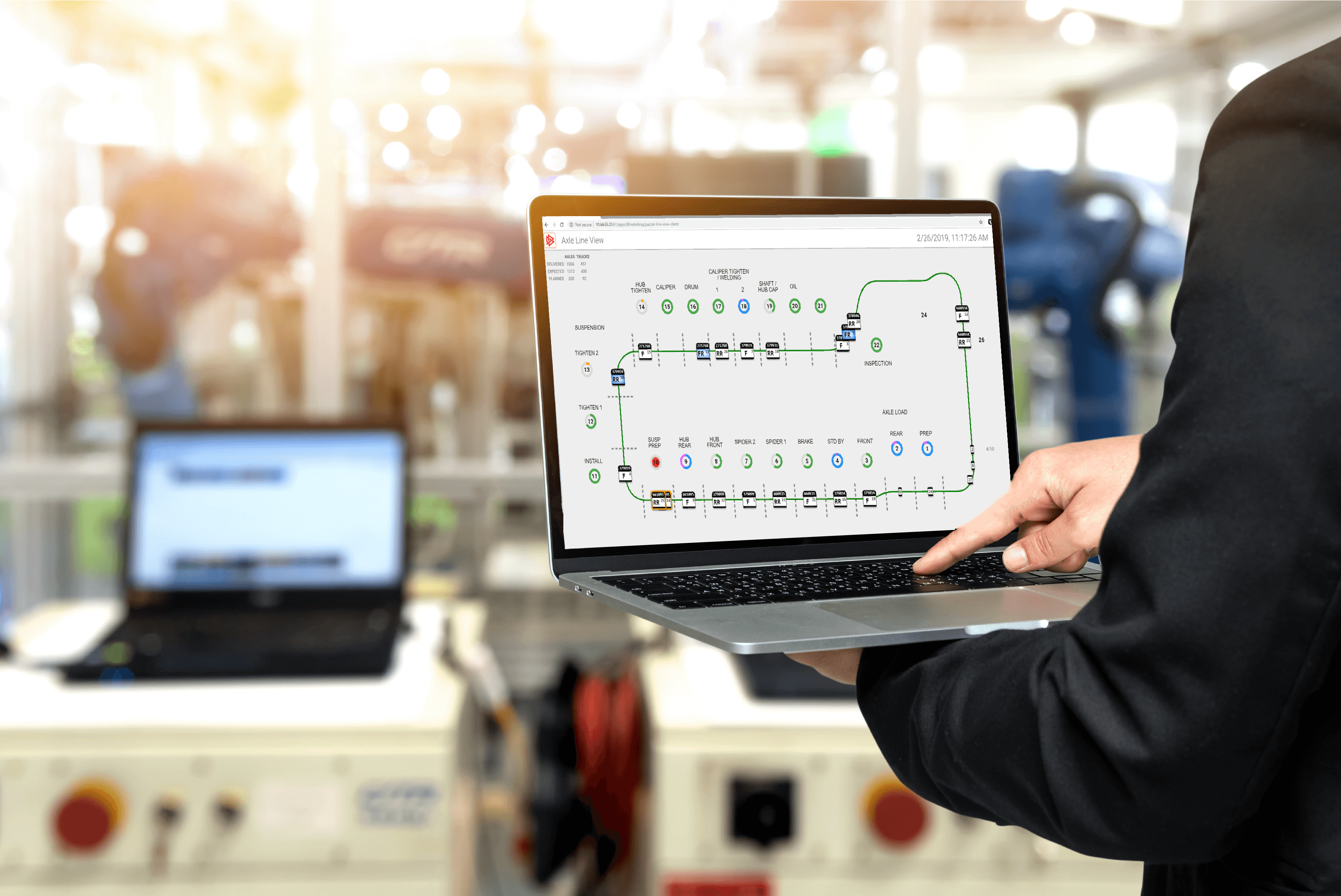

Applet Runners allow user-defined applications (Applet Runtimes) to be run in the cloud or at the edge. Applet Runtimes maintain a consistent state and connection to defined equipment allowing always-on headless operation. Operator views and interaction are web based and accessible from standard web browsers or mobile devices.

Applets integrate with MQTT and are Sparkplug-B compatible.