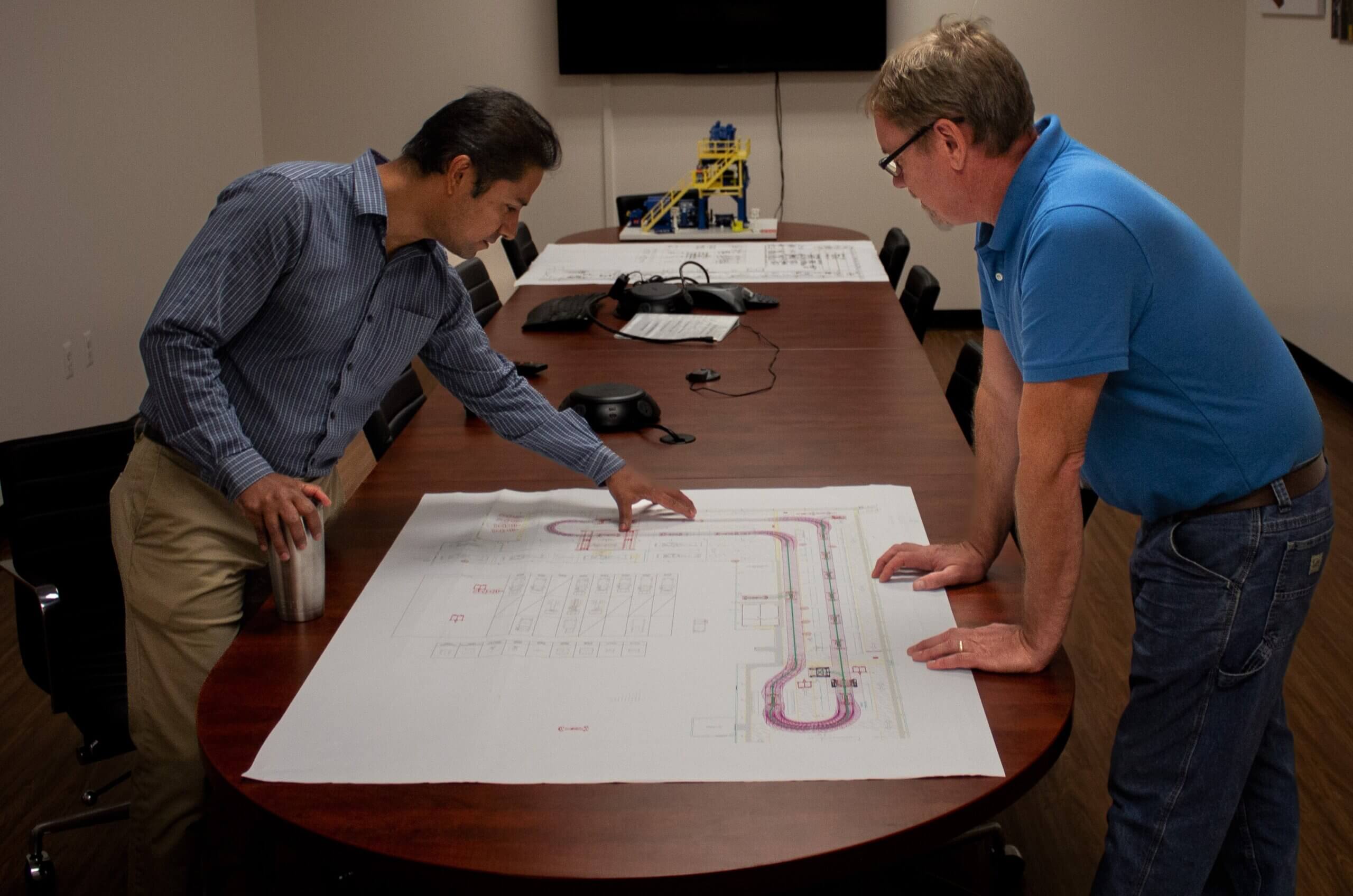

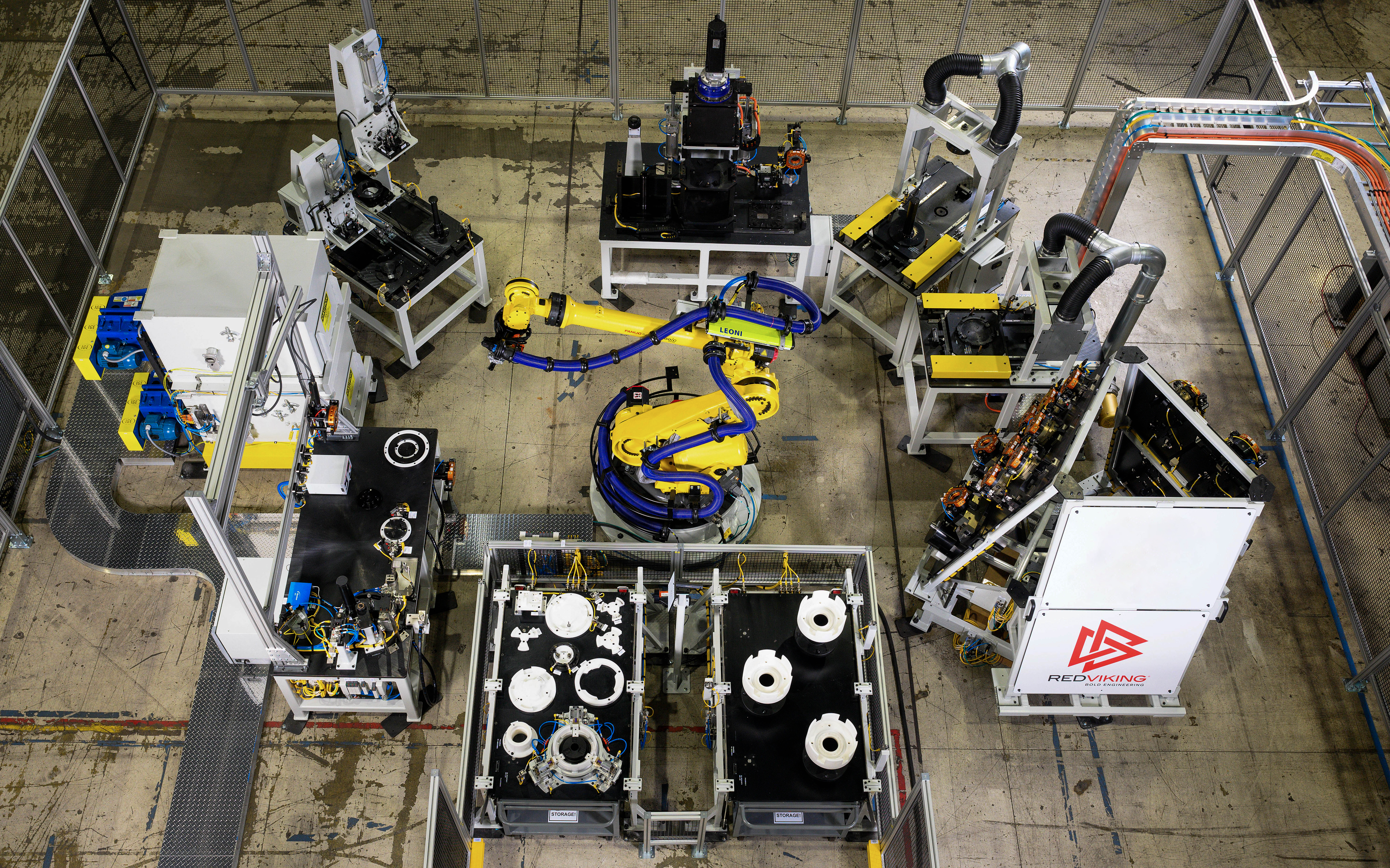

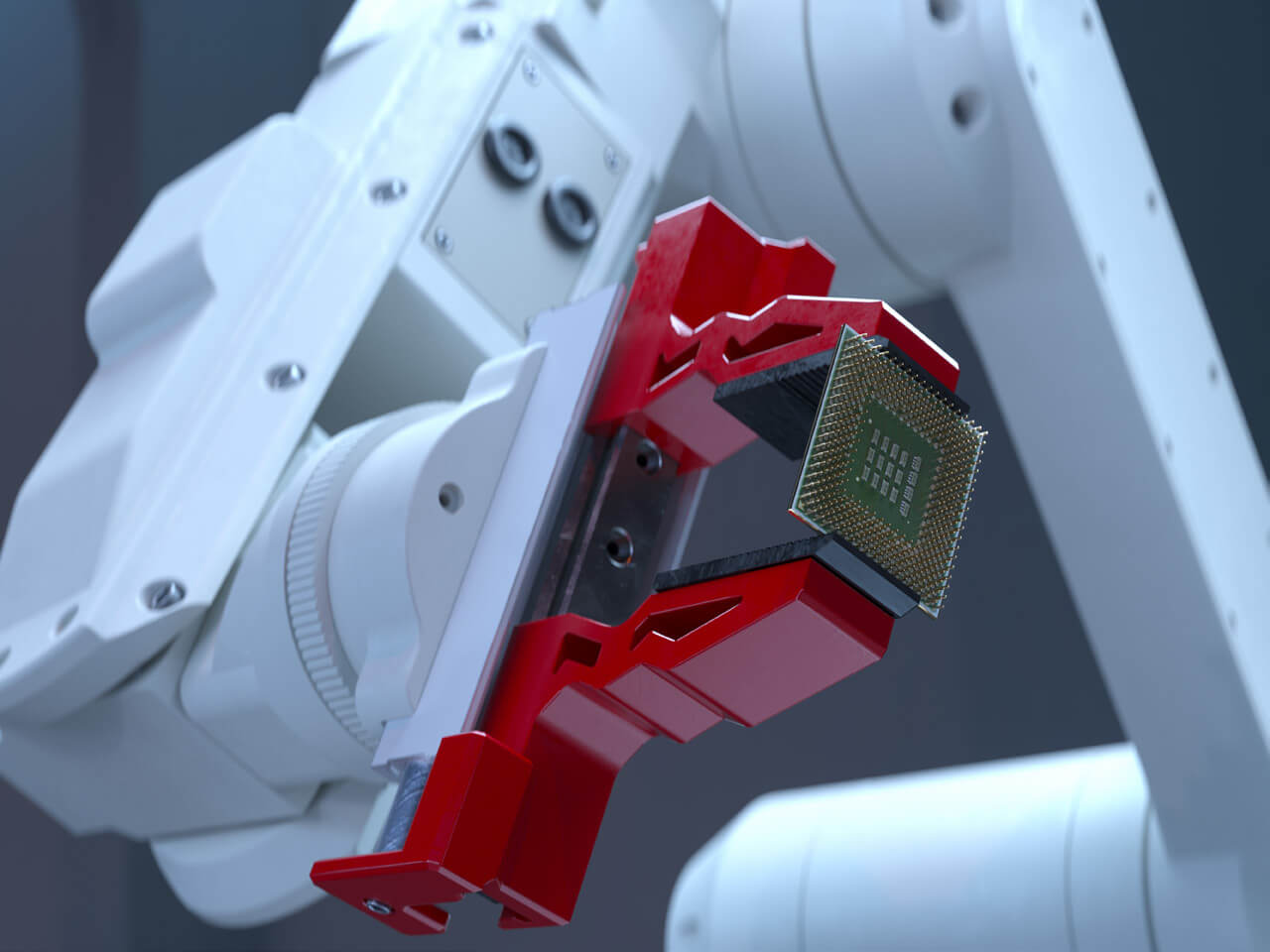

Process Engineering

Navigate the complexity of your production process with specialized expertise in production process engineering. We objectively analyze and consider all elements of your production, providing cost-effective, turnkey manufacturing services and automation solutions.