Red Viking Develops Creative Solutions to Automate Robotics Part Handling

Our Aerospace Customer needed to increase their current product manufacturing throughput capacity by over 50% while improving product quality. In addition, they needed a way to add tracking and traceability and improve the overall operator safety of their existing thermal manufacturing process.

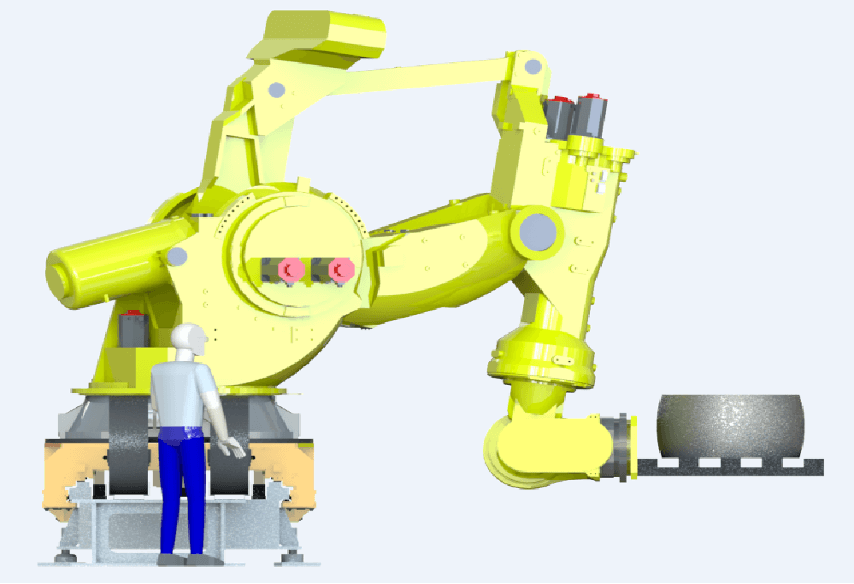

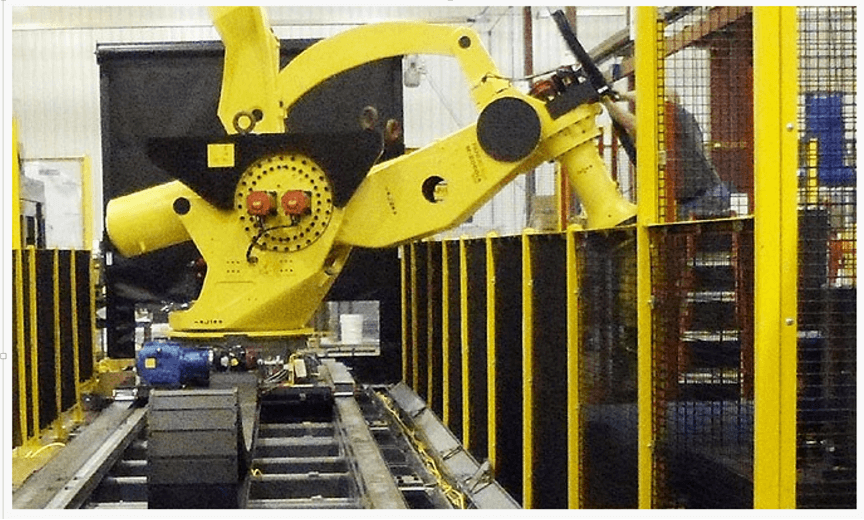

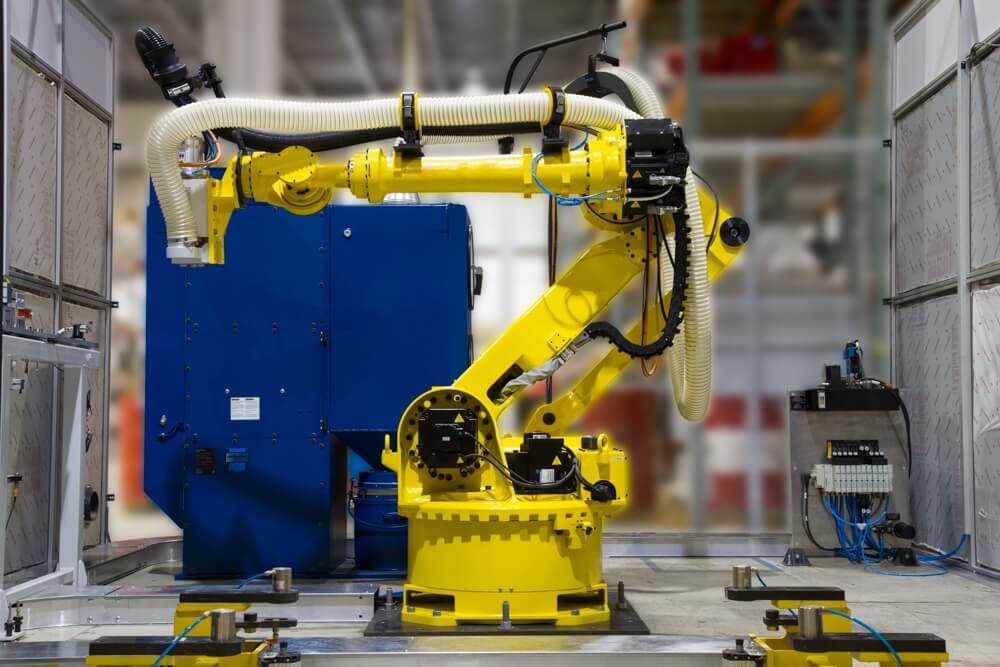

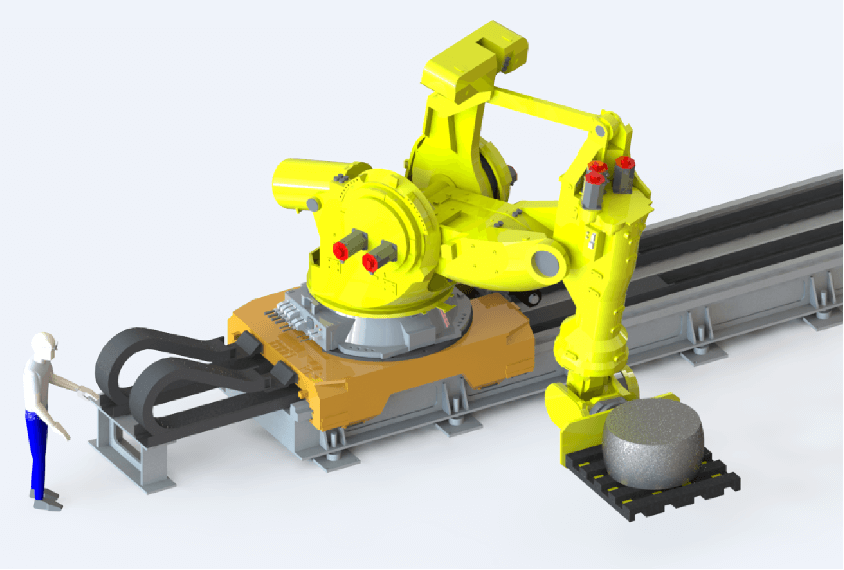

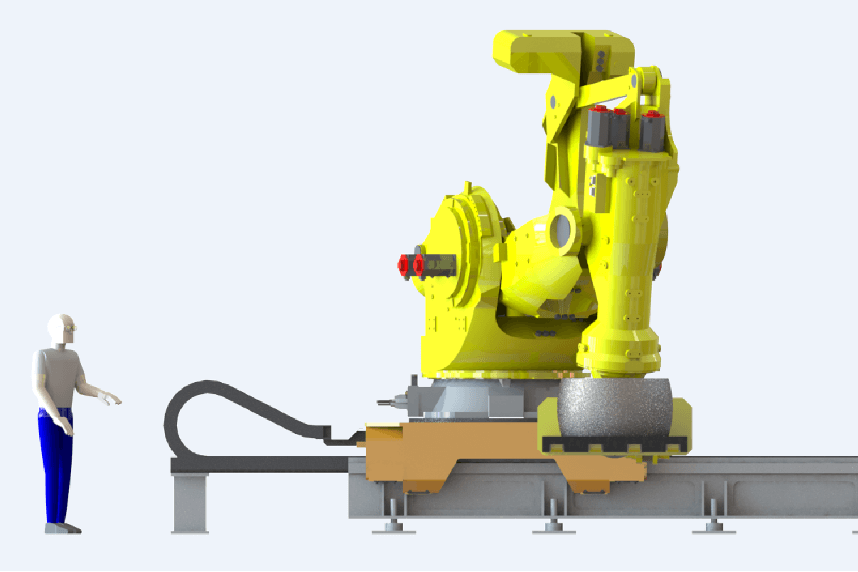

In order to meet and exceed our customer’s requirements, RedViking developed a fully automated Robotic based part handling and process machine tending cell. The turnkey RedViking solution proposed a fully automated robotics cell with a custom designed 7th Axis RTU system along with custom-engineered thermal compensated (EOAT) end of arm tooling and advanced safety control system. This fully automated cell will require operator intervention and provides automated load and unload stations as well as complete part tracking and traceability and advanced Fanuc Robotics safety solutions.

Key Benefits:

- 6 Axis Fanuc Robot Solution

- Custom engineered 7th Axis (RTU) Robot Transfer Unit

- Custom engineered RTU Location verification system.

- 2 HMI touch screen interface terminals at the Operator Load and Unload Stations

- Custom Engineered Thermal Compensated End of Arm Tools (EOAT)

- Safety Guarding, Gates and Switches, Safety Area Scanners and Captive Key System.

Custom Engineered Thermal Compensated End of Arm Tools (EOAT)

The fully automated robotic cell includes custom engineered thermally compensated End of Arm Tooling (EOAT) designed to handle the maximum part payload and extreme thermal temperatures with minimal sag at an optimal transfer speed to minimize the heat loss during part handling. A lift off Bayonet Mount EOAT exchange system and parking stand are included and are positioned in strategic locations for rapid change out capability.

Widescreen HMI Operator Interface Workstation Terminals.

The RedViking solution included two high resolution operator touch screen interface terminals controlled from the Cell Master Control Center. These redundant CE based PC HMI’s are the primary operator interface for local control as well and monitoring of all system functionality.

Safety Guarding, Gates, Switches Area Scanners and Captive Key Safety Systems

The RedViking designed Robotic Cell includes a Custom engineered free standing guarding solution with interlocked safety entrance gates at (3) key locations. The safety gates are electrically interlocked to the Cell Safety Controller and are an integral part of the advance robot cell safety systems that also includes area scanners and a captive key system together with a comprehensive LOTO system together providing a Category 4 safety compliance solution.