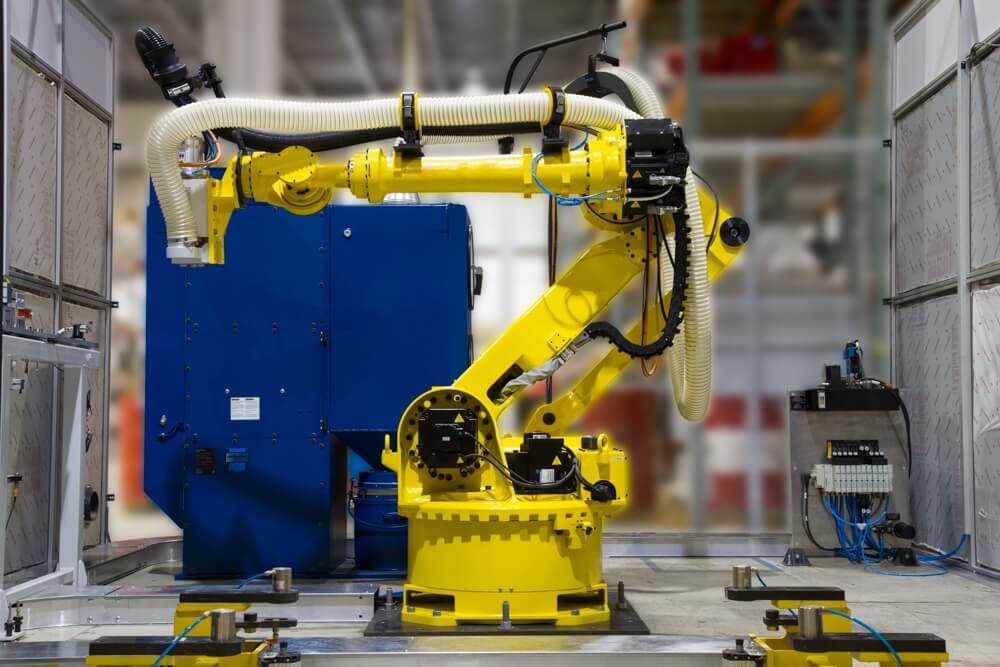

RedViking’s Custom Trim Cell Significantly Reduces Production Time

An aerospace manufacturer needed to cut production costs for part trimming. Their manual measurement and trimming process was time-consuming and costly. RedViking designed and built a custom automated laser radar aircraft measurement and robotic trimming cell. This cell was designed to trim six different parts within tolerance, reducing aircraft door and hatch trimming time from more than 70 hours to less than 10 hours per assembly. Our customer’s estimated first-year savings will exceed $2 million!

Key Benefits:

- 60-Hour Reduction in Process Duration

- Laser Radar Measurement Tool for Optimal Part Profiling

- Robotic Trim Within Tolerance

- Tool Changer Station for 6 Tool Types

- Automated Clamping for Ergonomic Load and Unload

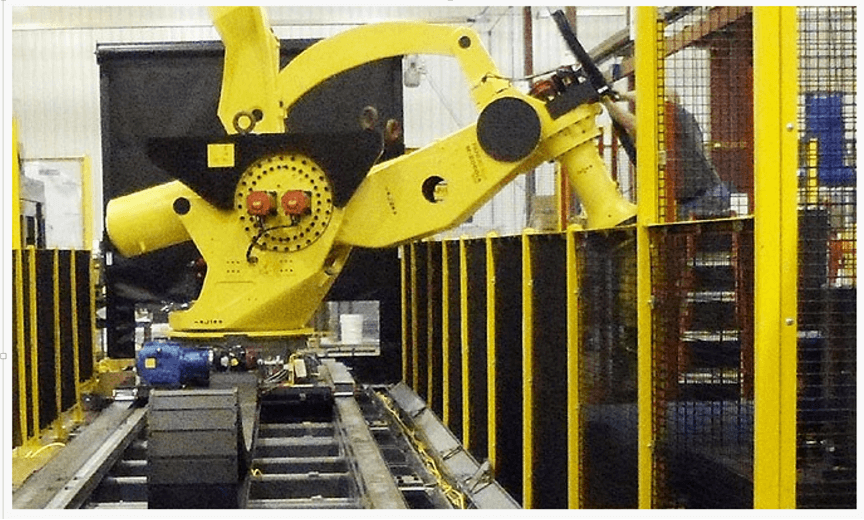

- 4 Transportable Fixtures for 6 Different Parts

Original Process Required Over 70 Hours

An aerospace manufacturer’s door measurement and trimming process was outdated and costly. Highly skilled workers were spending too much time on unskilled operations. Production time for each assembly exceeded 70 hours because each aircraft opening was measured and trimmed to fit by hand. This manual process involved many iterations of measuring the opening, trimming the panel, and placing it to test fit.

Laser Radar Data Integration for Robotic Trimming

RedViking integrated a laser scanning system that measures airframe openings and interprets the coordinate data for a trimming robot. Custom algorithms were created to translate the laser radar measurement data into a format usable by the robot. The system can robotically trim 6 different door types to the appropriate tolerance. The complete process now takes less than 10 hours.

Key Design Features Improve Operator Safety

Operator safety was a key element of our design because the manual process involved significant lifting and bending. The design includes clamping assemblies that allow the operator to load and unload the parts with ease. During trimming, an integrated vacuum collects dust and debris to prevent operator inhalation of potentially harmful particles. The robot cannot be operated unless the cell door is closed. Additionally, 5 emergency stop buttons are quickly accessible within the cell.

Positive Return on Investment in Less Than a Year

With RedViking’s intelligent automated solution, the manufacturer’s part trim time was reduced from over 70 hours to less than 10 hours for a single airframe. It is now a one-person job that takes less than one day’s worth of work. The manufacturer has predicted a positive return on investment in less than a year.

Precision Trimming Within Tolerance

Our Automated Aircraft Measurement and Trimming Cell vastly improves the manufacturer’s measurement accuracy and consistency, which results in a reduction in cost. Further, the new system also frees up skilled operators to do more valuable work.

Decades of Aerospace Experience

The customer selected RedViking because of our extensive expertise in designing and building custom machines, automation, tooling, software, and controls – and seamlessly integrating them. We are doing projects for fixed-wing assembly, jet engine test and assembly, helicopter dynamic component testing, and more. If you have an aerospace test or assembly challenge, we will work with you to design the solution that fits your timeline and your budget, with outstanding support for the life of your machines.