We’ve got a proud history of protecting U.S. military troops while also protecting taxpayer dollars. On March 29th – 31st, we’ll be at the Army Aviation Association of America Mission Solutions Summit in Nashville, offering a view into some of our newest dynamic test technologies and custom specialty machines. If you’ll be there, stop by Booth #502 to see us.

Better Safety for Troops and Operators

We’ve been providing highly engineered solutions to the U.S. military for many years. When the Mine-Resistant Ambush Protected Vehicle (MRAP) was successfully protecting troops from IEDs, we designed and built a turnkey assembly line that increased MRAP production by 400% in 6 months. When obsolete technology threatened to limit the availability of munitions for all U.S. branches, we created a staged machine design and implementation program to sustain their 1,200 parts per minute production requirement. All of our systems emphasize safety for the operators who maintain and repair them.

Highly Engineered Solutions for the U.S. Military

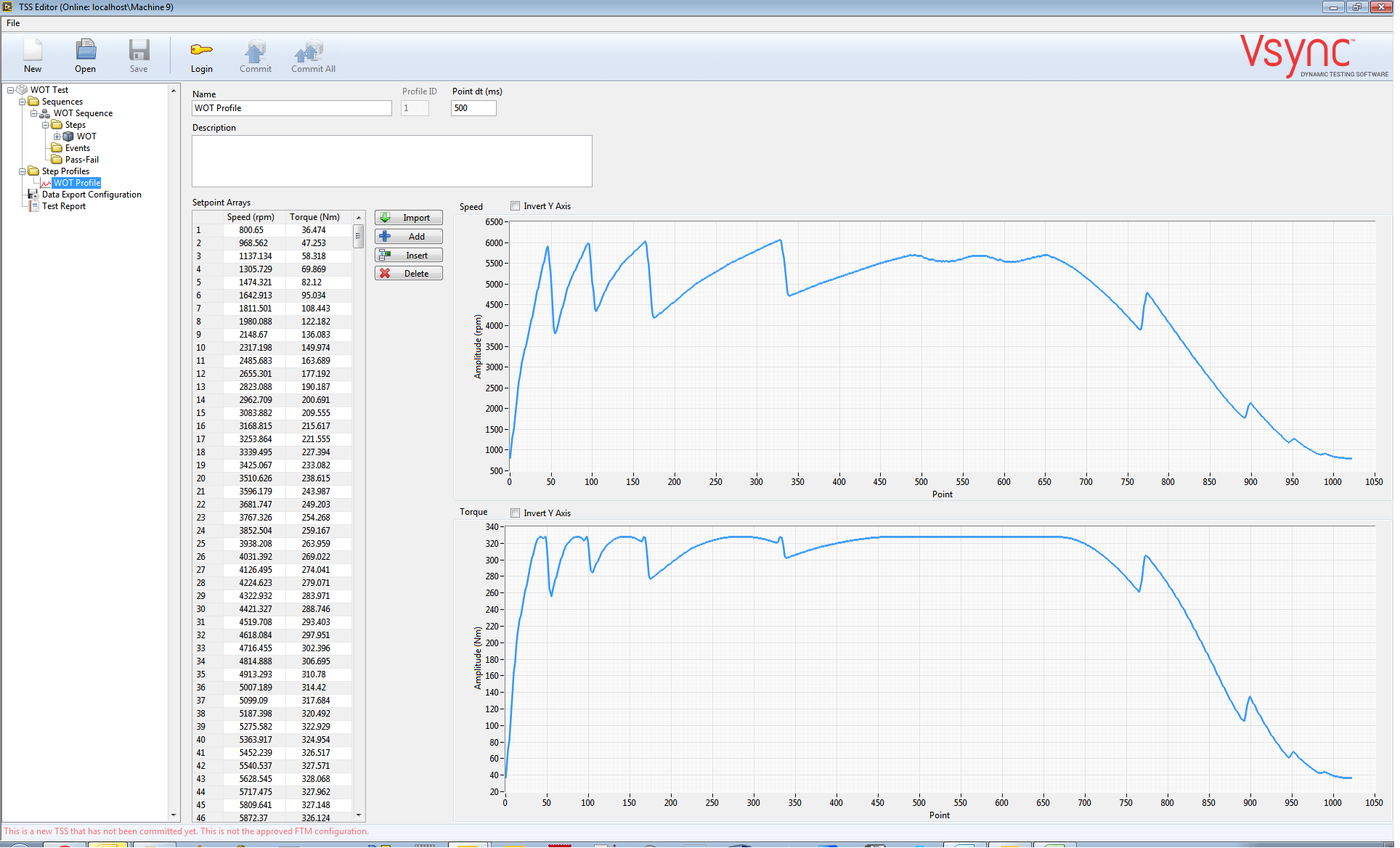

Recently we’ve been implementing advanced technology for some of the largest military helicopter centers in the world. We’re currently working with U.S. Army and U.S. Navy helicopter engine and powertrain test centers to improve testing quality and cut costs. By using electrical energy regeneration, we’re also helping them to significantly reduce power consumption. We’ve built barrel cooling controls for the U.S. Navy, leak test systems for the U.S. Army, and much more. In peacetime as well as in conflict, we’re proud to bring excellent support and service to our military customers.