The assembly line has paved the way to mass produce just about anything. But today, with consumers demanding customization on an ever increasing level, manufacturers are faced with producing high volumes in hundreds of variations. Managing the lineside parts inventory to support all of that complexity can be one of their most difficult logistical challenges.

Overcrowded Assembly Lines

We recently partnered with an automaker that needed to add more models and styles to their production line without increasing floor space. Their assembly line was already overcrowded with parts, and the addition of new variations seemed almost impossible. Operators were frustrated with time wasted searching for parts and managers needed to eliminate line interruptions caused by part shortages. It was critical for them to have a better method of delivering parts to the line, sequencing them for installation, and verifying proper placement.

Better Control of Part Supplies

First, we worked with them to create a sequencing system for better control over their lineside part supply. Using vehicle build schedules and component data, parts are now organized for a constant just-in-time inventory. Off the line, part supply staff uses handheld scanners with bar code and RFID systems to scan and stagger or reverse order parts on racks before delivering them to the assembly line. Sequencing instructions are automatically updated based on real-time production schedules, and information is constantly communicated to the part supply team. An automated real-time sequencing system significantly reduced the amount of lineside space required for part storage. Operator walk paths were improved and production slowdowns were significantly reduced.

Optimized Inventory & Work Space

Another part of the problem was the fact that all part kits were located beside the line, and part storage overcrowded the floor. Infrequently used parts took up valuable space. Excess ordering occurred when parts went unnoticed in remote areas of the plant. Two types of kitting systems were the answer. For both, part supply teams scan and place necessary parts for a model build into a container and then sequence them according to the production schedule. Beside the line, stationary kits contain parts common to virtually every vehicle. Station HMI’s direct the operators to their next part selection. Each station’s lineside kitting system is structured around their process and may include start and stop sequence lights, a printed parts list, or light indicators on each bin. Visual instruction is provided for each step. The second type of part supply is a ride-along kit of reverse sequenced parts for unique assemblies. In this way, infrequently used parts don’t take up unnecessary floor space, but travel on the vehicle floor throughout the build. With stationary and mobile part kitting added to sequencing, operator efficiency improved further and product quality was enhanced.

Integrated Error Proofing

Finally, automated error proofing systems were integrated to further ensure part availability, proper selection and accurate placement. The system enables off-line part pickers to prevent shutdowns due to part shortages, as light indicators now notify them of low part inventory or improper bin placement. On the line, automated torque measurement and vision inspection systems check for incorrectly placed or absent parts. The resulting part placement error proofing data is now integrated with final end of line inspection and becomes part of each vehicle’s birth history. We incorporated these systems with the auto supplier’s network to communicate plant-wide through Andon boards, web clients and handheld devices.

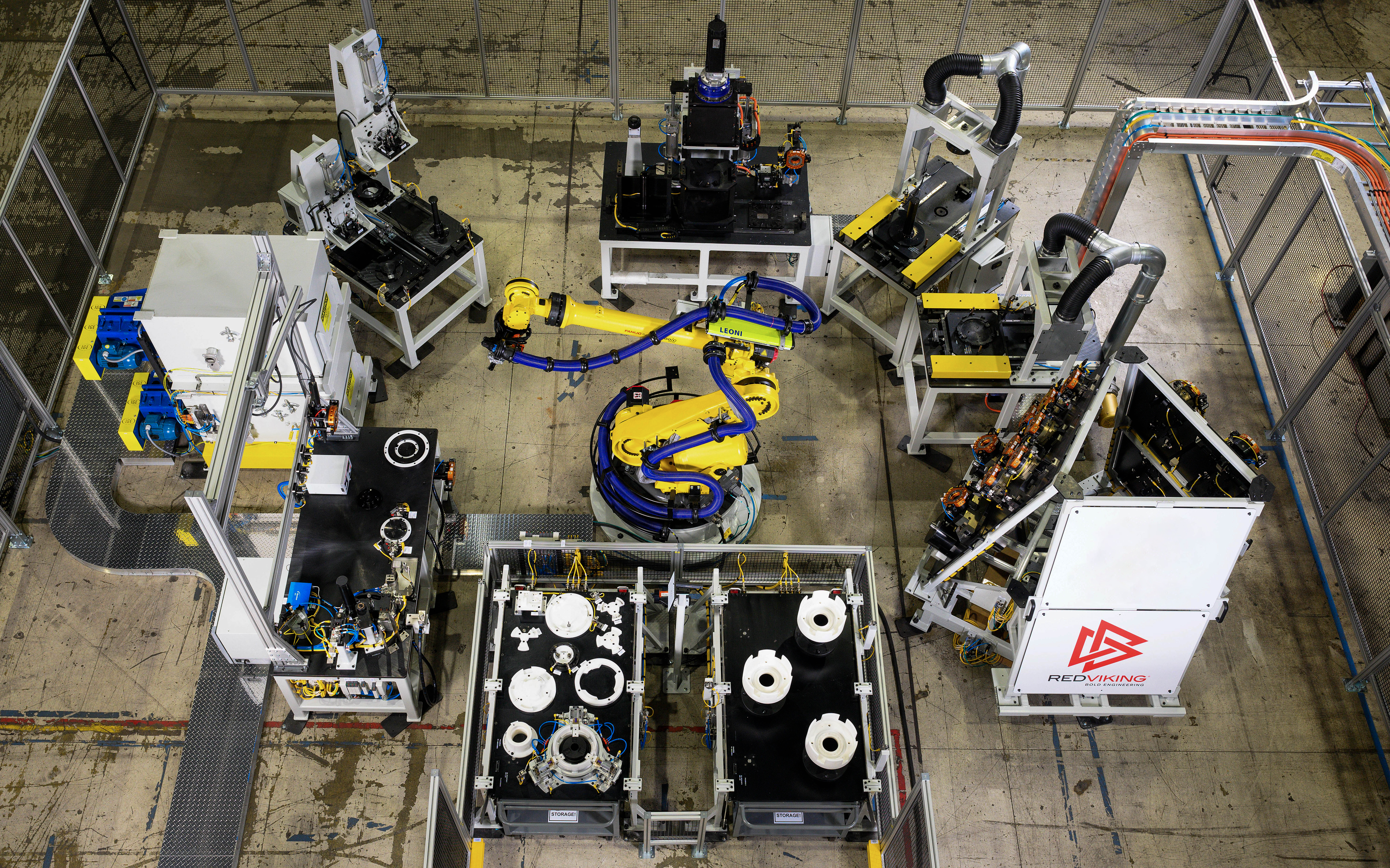

Automated Parts Management

Doing more with less is critical to remaining competitive in manufacturing. In the same space where our customer used to produce dozens of variations on a line, they now produce hundreds of vehicle variations with higher quality and greater efficiency. I’m always game to talk production quality and efficiency. You can reach me at ggiles@redviking.com.