This is an excerpt written by Automation World, featuring Josh McNeely, Vice President of Sales and Marketing at RedViking

Automated guided vehicles can provide flexible paths and processes, scalability, flexibility and intelligence in rapidly changing markets.

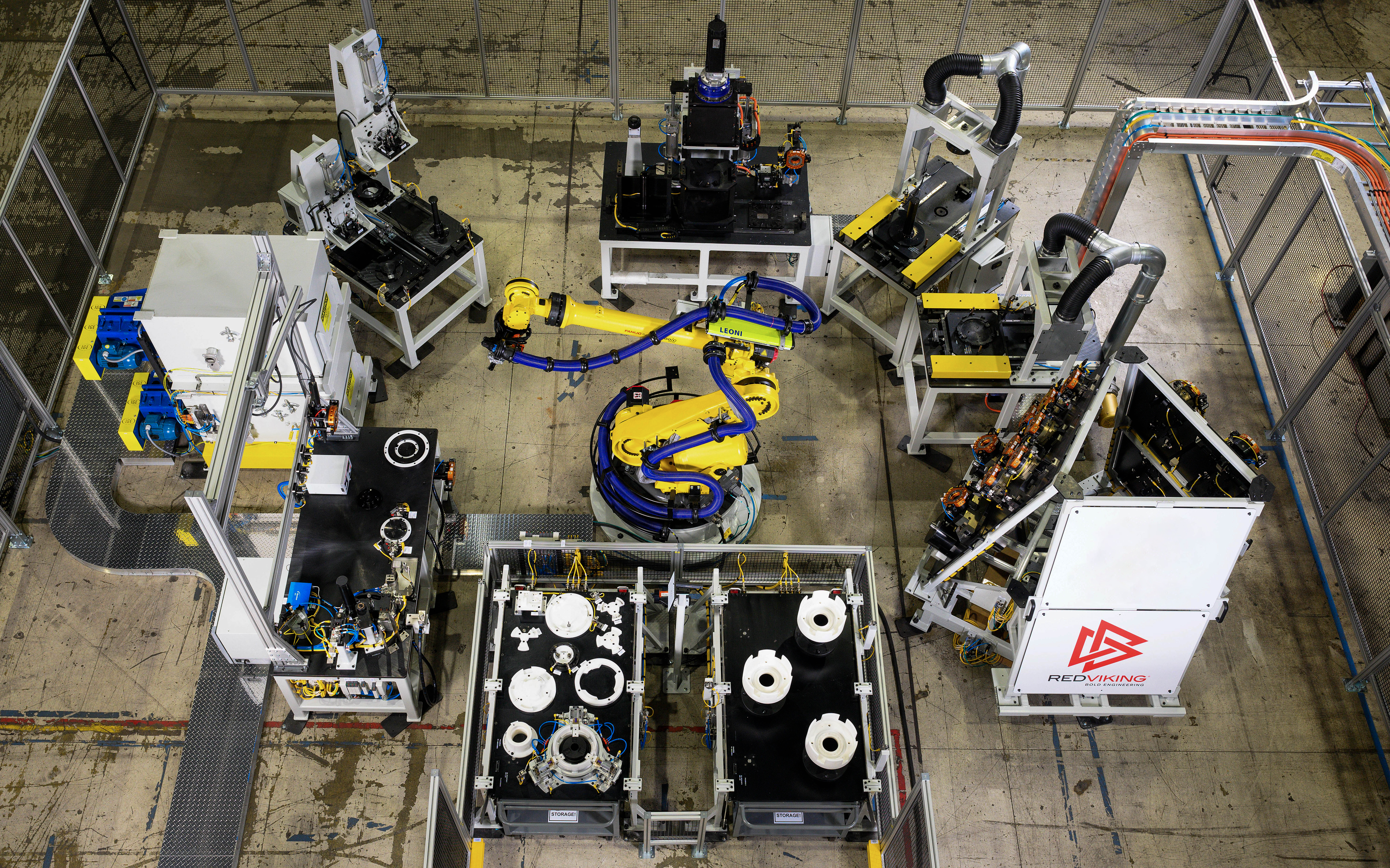

We’ve installed more assembly-line automated guided vehicles (AGVs) for manufacturers in the past few years than ever before. The global economy is rapidly changing and we’re seeing a strong demand for manufacturing solutions that can respond quickly to those changes. Many customers don’t know what questions to ask or what technologies might be options or what solutions to apply. AGVs are a perfect fit for assembly lines and material handling where you need 24/7 operation, onboard power for lift or rotation, high duty cycles or heavy payload transport. So how do you know if AGVs are a fit for your plant? Do you need flexible paths and processes? Traditional conveyance doesn’t offer flexibility in paths, processes or products. With pits, chains and metal tracks, it is dirty, noisy and expensive to change out. It doesn’t allow manufacturers flexibility to make changes in an environment that must be able to do so.

Whether through inductive power transfer, magnetic tape or geolocation, AGV paths can be quickly changed. There are typically few monuments involved, even for very heavy and complex products. If the AGVs have an onboard programmable logic controller (PLC), they can be reprogrammed to respond to process changes by spending less time in station, advancing asynchronously, requiring process completion for advancement, and more. Do you want to be able to scale as you go? Product launches often entail some type of ramp-up, with limited initial production preceding full throughput rates. With traditional chain-based conveyance, manufacturers essentially have to buy all the conveyance they’ll ever need, before they really need it. It’s generally not practical to install part of an overhead power and free track, or just a few skillets. Instead, they have to make the full conveyance investment at the start of the project, even if they won’t be up to capacity for some time. AGVs allow a staged investment. Companies can buy only the number of AGVs they need for initial launch, adding AGVs as they increase production rates. This approach reduces capital outlay, lowers risk, and better aligns production expense with revenue. Do you produce various model types?

AGVs allow a staged investment. Companies can buy only the number of AGVs they need for initial launch, adding AGVs as they increase production rates.

There’s debate about whether or not product lifecycles have actually shortened, but it’s clear that the single-product assembly line is becoming a thing of the past. Multi-model production is more and more the norm. Conveyance that’s designed around a single product or set of products is inherently expensive to change. We’ve seen that for decades in automotive manufacturing, as most automakers scrap thousands of pounds of conveyor metal for every major model change. Since they’re not physically attached to the building, AGVs are more suitable for multi-model and periodically changing assembly lines. AGVs can create a moving surface with power for onboard lift and rotation. By including quick-change clamping mechanisms, positioning fixtures and tool attachments, one AGV can handle a variety of products. Do you need an intelligent conveyance system? With onboard PLCs, AGVs can interact directly with a manufacturing execution system (MES), allowing the integration of error-proofing, traceability, part kitting and more. For example, on an asynchronous multi-model assembly line, an AGV can refuse to advance until all error-proofing checks are complete. If an error is deemed unresolvable within takt time limits, the AGV can reroute to a repair track. Traceability and overall equipment effectiveness (OEE) systems will identify that the product has moved off the main line and log the fault that required the diversion. Part kits will be adjusted ahead to address the change in the build schedule. The AGV becomes an intelligent component of the entire system, with the ability to engage with the plant MES, rather than a “dumb” mechanical chain device. Do you want to learn more about AGVs? Use our contact form or email us at engineering@redviking.com. Our phone number is 1-734-454-0500.