No Batteries Required

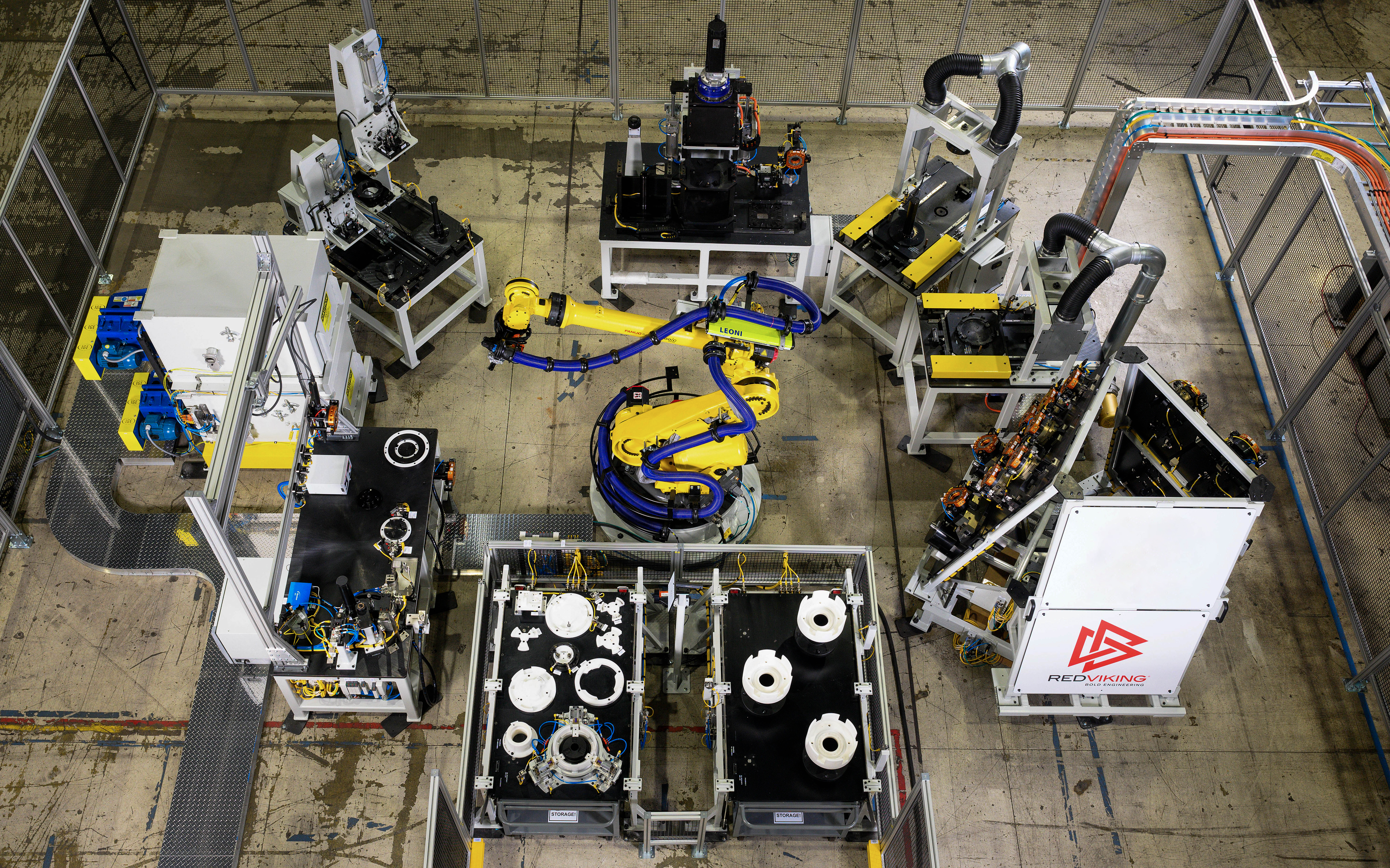

If you’ve ruled out AGVs because they’re not powerful, durable, or intelligent enough, you need to check out RedViking’s battery-free AGVs. We’ll be in Booth N1807 at Automate/Pro-Mat 2017 in Chicago, showing off our Wingspan Battery-free AGVs for both assembly lines and material handling.

Much More Than a Warehouse AGV

Battery-free AGVs are not your typical warehouse AGV. They’re for assembly lines and material handling when a battery-powered AGV just won’t cut it, for example when you need:

- Continuous operation without having to replace or recharge batteries

- Onboard power for lift, rotation, or positioning

- Onboard intelligence for variable paths, processes, and speeds

- Heavy or variable payload transport

24/7 Operation – No Charging Stations

Continuous operation is always critical for assembly lines, but it’s often critical for material handling as well. We’re working with companies who need to move parts or products along a predictable path 24/7, and they don’t want to disrupt their operation to replace batteries or send an AGV to a charging station. Inductively powered Wingspan AGVs can operate without interruption because they’re constantly receiving power as they travel.

Onboard Power for Lift, Rotate, Position

To operate an onboard lift, battery-powered AGVs require frequent recharging. And given the fact that battery life is notoriously unpredictable, there’s always a risk that the lift will stop working mid-task. With 2.5 kW of onboard power, battery-free AGVs can operate lifts, rotating fixtures, robots, and more without ever having to recharge.

Part of Your IoT Architecture

Because Wingspan AGVs are intelligent devices with onboard PLCs, they’re part of your information network. They can constantly offer data to be used in tracking, traceability, productivity analysis, and more. Using Argonaut or your own MES, the AGVs can act as IoT devices to broadcast data to subscribers like feeder areas and shipping. Battery-free AGVs can have constant awareness of path, process, and payload. This allows them to follow a branching path based on what they’re carrying, and interact differently with different parts of your facility. These AGVs can slow down not only when they sense an obstruction, but also when they need to change speeds based on a specific process or location.

From Light to Very Heavy Payloads

We’ve designed battery-free AGVs to carry a few hundred pounds, and we’ve designed them to carry a few hundred tons. Because there is never a worry about battery life, Wingspan AGVs can carry anything from a pallet of lightweight packages to a construction vehicle weighing hundreds of thousands of pounds. If you’ve looked at AGVs but had to rule them out because their battery life wasn’t sufficient for your payloads, RedViking can help. Want to learn more? Fill out our Talk to an Engineer form, email us at engineering@redviking.com, or call us at +1.734.454.0500.