Turnkey Engineering and Manufacturing Solution

A Department of Defense ammunitions manufacturer was desperate for a solution to make major line technology improvements while meeting their high volume requirements. They were facing high maintenance, frequent machine failure, and obsolete components that were extremely difficult to replace. The line needed to meet its high-speed production and inspection requirement of 1200 parts per minute. It seemed impossible to meet these requirements for greater throughput seemed impossible in the face of frequent downtime.

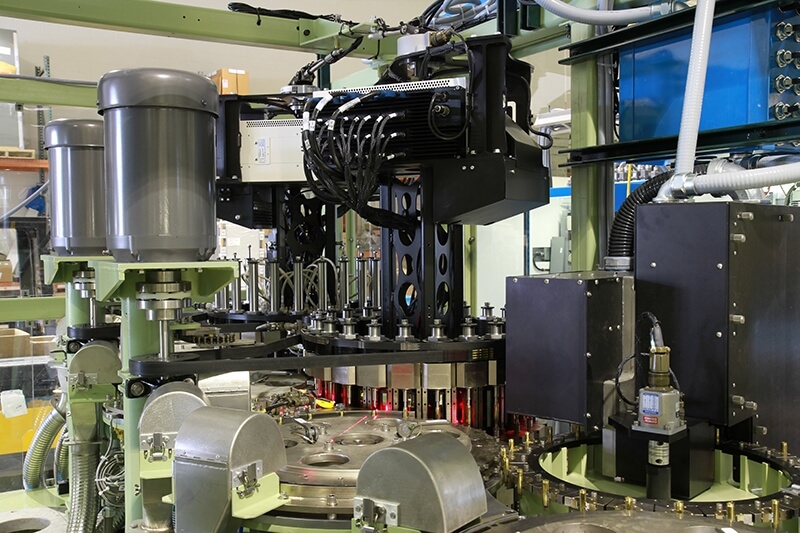

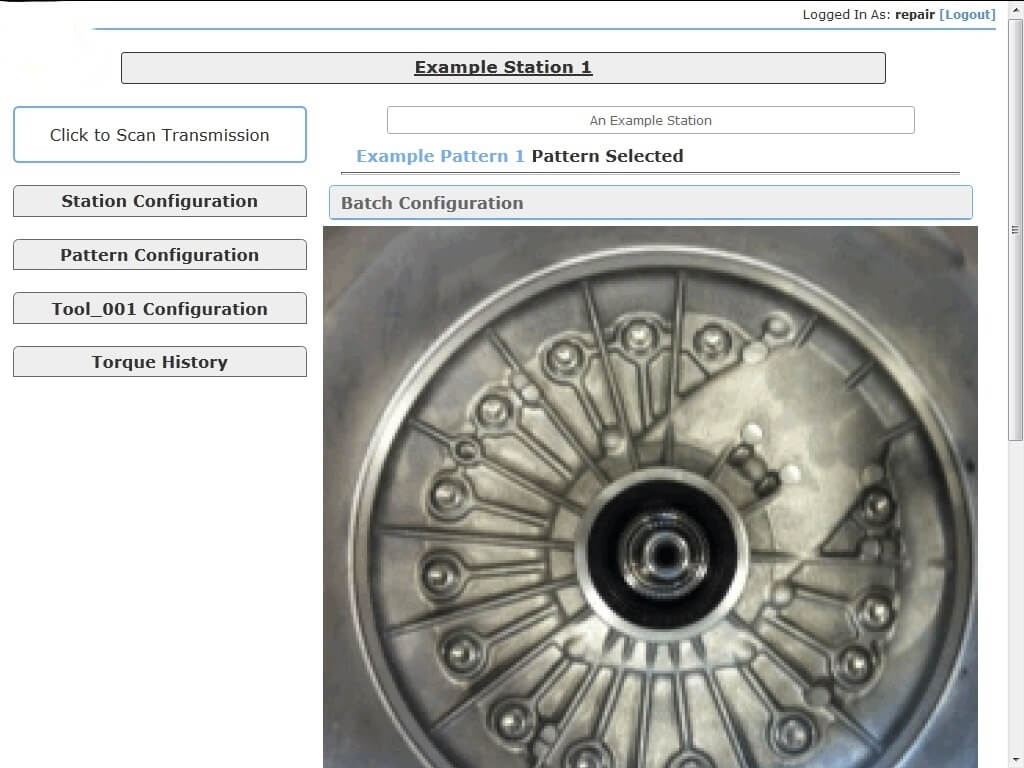

RedViking created and managed a turn-key solution for mechanical design, build, and installation of all machines, software and controls systems. A new line was designed that would use existing equipment when possible to minimize costs. The first system was built from the ground up to serve as a prove-out and was inserted into the line with minimal disruption.

Key Benefits:

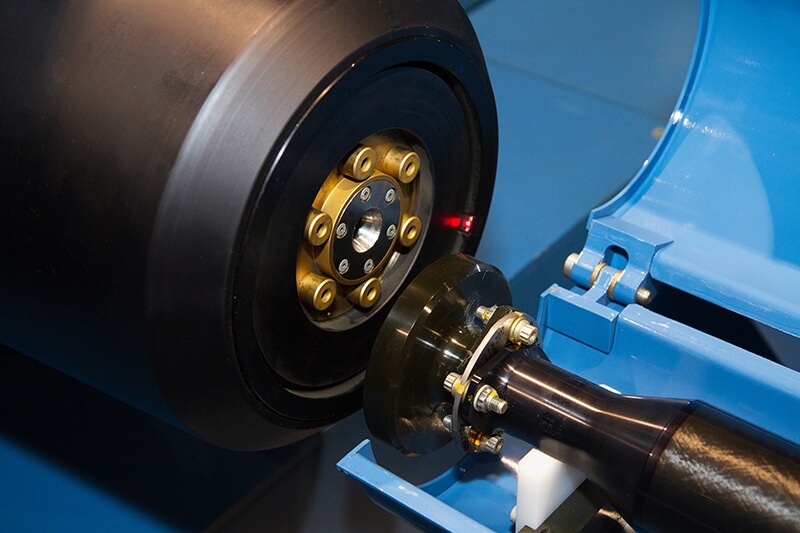

- In-Line High-Speed Production, Test, and Inspection Systems

- Complete Project Design and Implementation Minimized Line Disruption

- Refurbishment Was Chosen Over Replacement Wherever Possible to Reduce Cost

- New Technologies Were Inserted to Significantly Improve Product Quality

- Turnkey Installation Allowed the Customer to Remain Focused on Their Existing Roles and Objectives

- Increased Throughput Objectives Were Met and a More Cost-Effective Line is in Place

The Right Blend of New and Refurbished Machines

Once the initial system had proven its speed, maintainability, and sustainability, existing systems were refurbished to match it. The most current technologies and readily available COTS components ensure that the manufacturer is now able to meet increased product demand with vastly improved system availability. We were proud to manage this complex project such that none of the munitions lines were taken down during modernization.