Shriraj Gaglani (far right), vice president of product development at Microsoft, moderates a panel discussion that includes Joshua McNeely of RedViking, Blake Carlson of Weavix, and Adrian Bolliger of Datwyler IT Infra

RedViking’s Chief Commercial Officer, Josh McNeely, recently participated in a panel discussion at the Hannover Messe, a renowned industrial technology trade fair held annually in Germany. The panel was led by Microsoft’s Shriraj Gaglani to discuss the value of the developing technology and how modern connected apps can help to improve industrial operations. During the discussion, McNeely spoke about RedViking’s innovative 5G connected Automated Guided Vehicle (AGV) solutions and Argonaut software solutions, which are revolutionizing the way manufacturing facilities operate. Included alongside McNeely on the panel discussion was Adrian Bollinger of Datwyler IT Infra and Blake Carlson of Weavix. Read below to learn more about the panel discussion and how RedViking, Datwyler IT Infra, and Weavix are leveraging new technologies.

The following is an article originally released by Technology Record written by Richard Humphreys on April 18, 2023

Microsoft’s Shriraj Gaglani leads the discussion about the value of the developing technology and how modern connected apps can help to improve industrial operations

Microsoft highlighted the value of 5G and modern connected applications for industrial operations during a panel discussion on the first day of Hannover Messe 2023, which is taking place in Hanover, Germany, from 17-21 April.

Shriraj Gaglani, vice president of product development at Microsoft, moderated ‘The Value of 5G for Industrial Operations’ panel, which also featured Blake Carlson, chief strategy officer at Weavix; Joshua McNeely, chief commercial officer at RedViking; and Adrian Bolliger, managing director at Datwyler IT Infra.

“We’re seeing a very strong pattern of demand across many different industry verticals who are looking to transform themselves with 5G,” said Gaglani. “Their focus is on these modern connected applications – video artificial intelligence, the robotics and automated guided vehicle [AGV] space, frontline workers and industrial internet of things [IoT] – with each bringing a unique value proposition to the manufacturing space.”

The moderator outlined how these modern connected apps have delivered “staggering business outcomes” for Taiwanese manufacturing companies Inventec and Pegatron. “They have started incorporating private networks with local edge computing at their factories,” said Gaglani. “By using a combination of video AI, AGVs and industrial IoT solutions, they’re starting to see some significant improvements in key metrics like production yield and reduced downtime.”

With 5G paving the way for modern connected applications, Microsoft’s Azure Private Multi-Access Edge Compute (MEC), which combines edge-optimised compute, networking and Azure services with independent software vendor (ISV) applications, addresses the business needs of enterprise customers.

Integration with Azure private 5G Core allows ISVs to leverage simple, scalable and secure deployment of private 5G networks. The ISV programme for Azure private MEC has been designed to accelerate the development and adoption of modern connected applications for enterprises.

“We are building a marketplace and working very closely with these modern connected application ISVs to certify, pre-validate and make sure their applications work out of the box,” said Gaglani. “So, we have an Azure private bank and private network marketplace now in Azure where it becomes easy to find this growing ecosystem of validated applications. Building these applications is also something that is new to most developers. Modern connected applications are hybrid by nature; they require a distributed edge compute capability such that the application is available wherever the user needs it, and by offering a community in our cloud-to-edge continuum for edge compute, we’re making it much easier for these developers to optimize the way they build their applications.”

Each of the panelists provided insight into their experiences of building and deploying modern connected applications.

“Our context is trying to build the best database we can on the frontline worker, which pushes us into data collection,” says Weavix’s Carlson. The company created the Internet of Workers platform that Carlson describes as “the next generation of frontline radio communication”. The platform provides facility owners, manufacturers and general contractors with a single place to manage both field communication and all contractors and employees.

“We’ve built a very interesting smart radio that does push-to-talk, push-to-text, push-to-video, archives all this data and then serves it up to management consoles for optimization,” said Carlson. “However, in the ISV business, you’re only as good as your partners, and the opportunity to work with Microsoft to not only consume cloud services, but, more importantly, to also deploy networks at the edge, close to where the network data can be collected, has been unbelievably impactful for our business. To deliver this solution under a managed server provider model with MEC has been unbelievably enabling for us.”

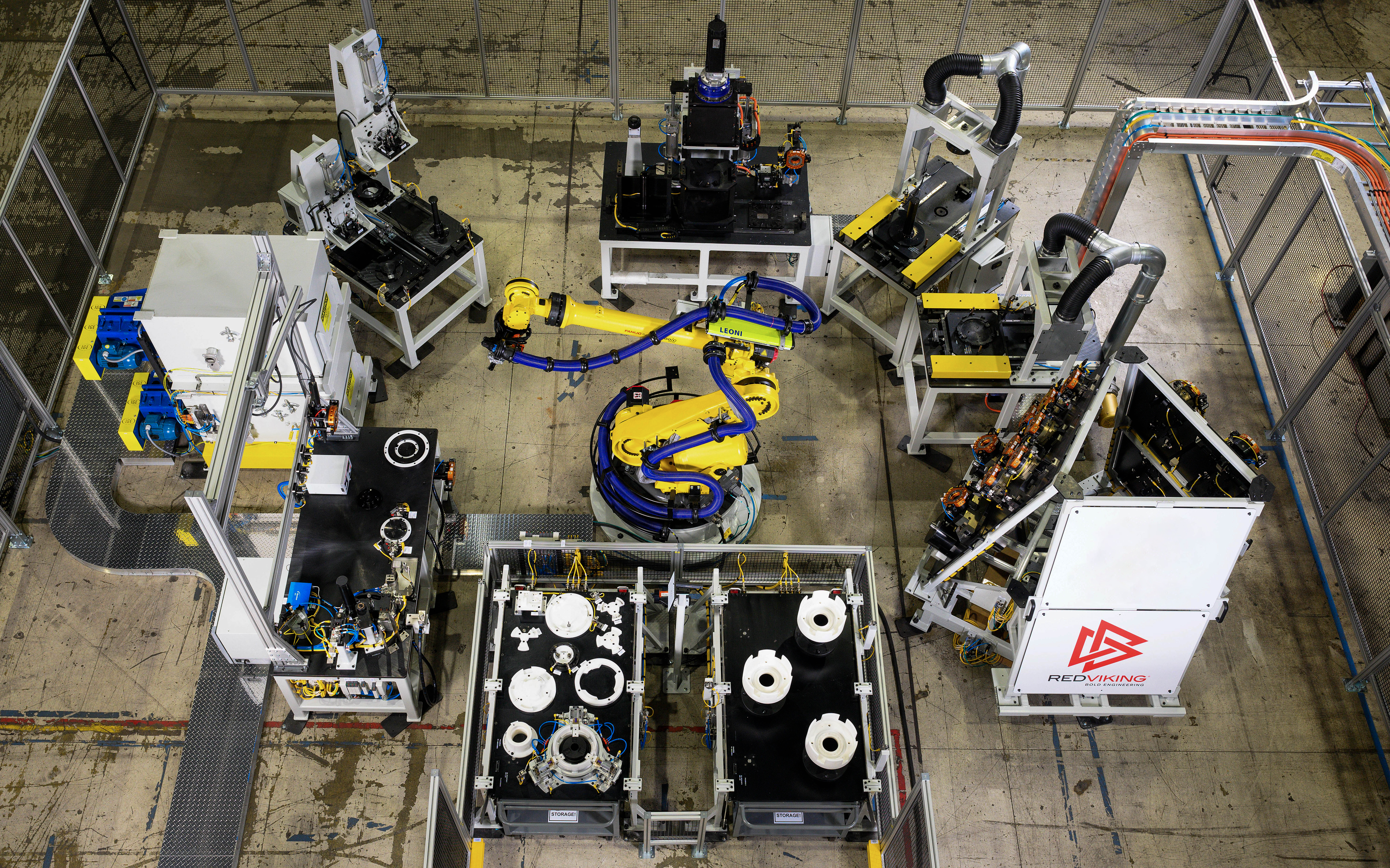

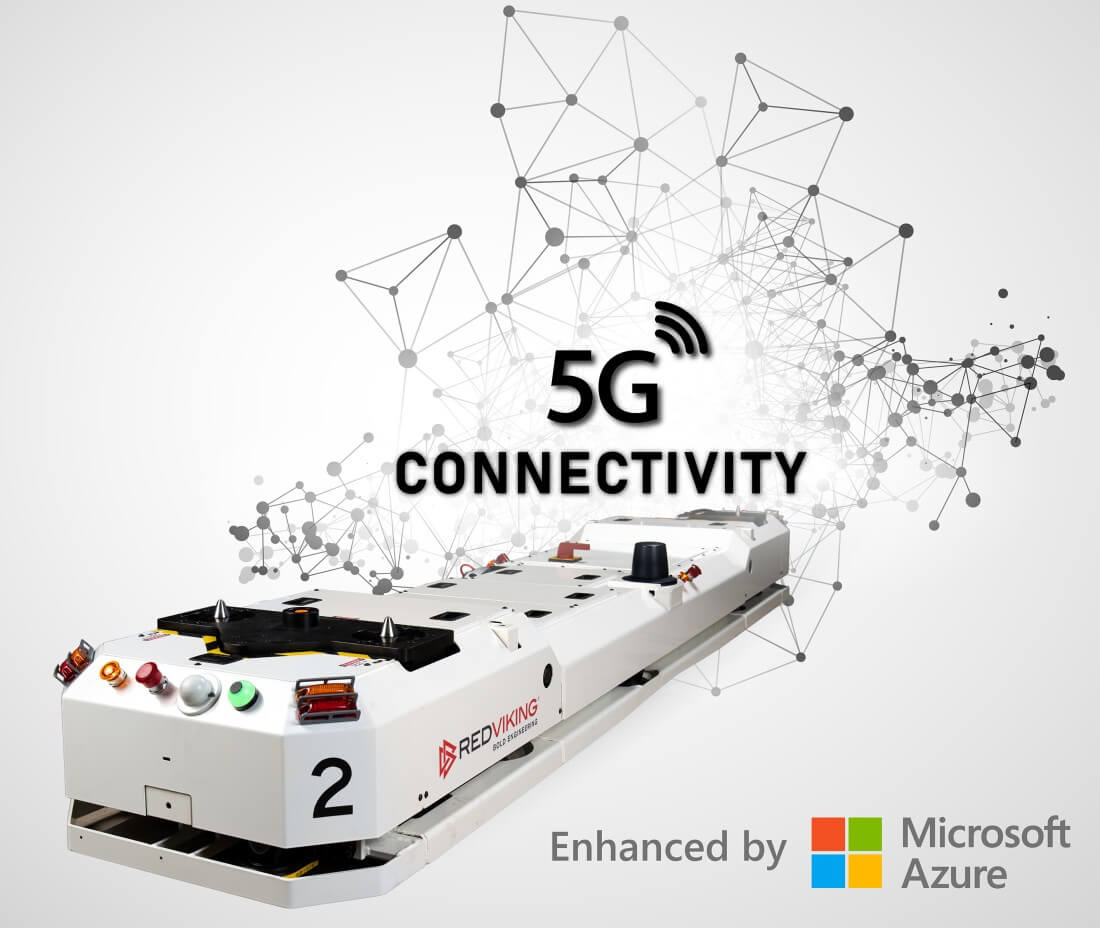

RedViking designs, builds and implements solutions to help organisations solve difficult manufacturing problems. “We’ve seen tremendous expansion in an application that runs on Azure called Argonaut,” said McNeely. “The platform connects our customers and manufacturing with mission-critical data that helps drive the production processes. Thinking in terms of worker instructions, digital work instructions, real-time location monitoring and tracking of finished goods, equipment, health monitoring, we’re seeing a tremendous impact on profitability and reliability within our customers. We’ve seen our customers really embrace the AGV as a mobile workstation – 5G allows us to do that by being able to isolate and allocate bandwidth to these devices.”

Meanwhile, Bolliger gave an example of how Datawyler worked with Microsoft to deploy modern connected applications for a construction project.

“We partnered with Microsoft to build a solution,” he says. “It was also the start of the foundation to digitize all processes on the construction side to make the concerned people more smart and more efficient. Every company that is on the construction site can have access to this content and use the solution. It is easily scalable for the future.”

McNeely discussed what advice he would give to companies in the manufacturing space that are considering investing in 5G. “What I would say to enterprises is to focus on competition,” he said. “It’s about providing more capability and more reliability at device level and because we can isolate and allocate that bandwidth to a device, we can ensure that uptime and reliability. AGVs are built around growth, flexibility and 5G is just a natural supplement to the AGV technology.”

Shriraj concluded the panel discussion by saying: “Manufacturing companies need these modern connected applications, which are underpinned by these private 5G networks.”