This large automotive customer was dealing with chain based assembly conveyance. Amongst various issues, this environment was noisy, had poor operator ergonomics, was dirty and limited worker access.

High Volume Automotive Assembly Line AGVs

Our customer’s main issues:

- Vehicles progressed throughout assembly with minimal line access and poor ergonomic positioning for workers

- Extensive maintenance requirements resulted in costly line shut-downs

- The chain conveyance assembly line was inflexible and difficult to scale

- The system fell short on sustainability due to chemicals required for upkeep and waste created

Requiring only two shallow grooves cut into an iron-free floor, path changes are now made quickly made with our Wingspan battery-free AGVs. Gone are requirements for floor pits, drag chains, hundreds of highly skilled changeover staff during shut down. The conveyor systems introduced numerous opportunities for trip hazards and slippage due to grease and oil dripping. Operator collisions with moving carriers and parts on a continuous the indexing conveyor also posed safety challenges. We replaced conveyance with battery-free AGVs that operate on a smooth flat concrete floor free of any obstructions and trip hazards will reduce the risk of these injuries. In addition, operator ergonomic positioning is greatly enhanced resulting in less worker injury. Line changes are made through software, controls and minimal floor changes rather than tracks and chains. Downtime and change costs are significantly reduced.

Battery-powered AGVs were Considered

Battery-powered AGVs were considered but ruled out because the factory AGVs needed to operate 24/7 without leaving the line or stopping to recharge. Also, batteries didn’t offer sufficient power to simultaneously move the vehicle and power the lift.

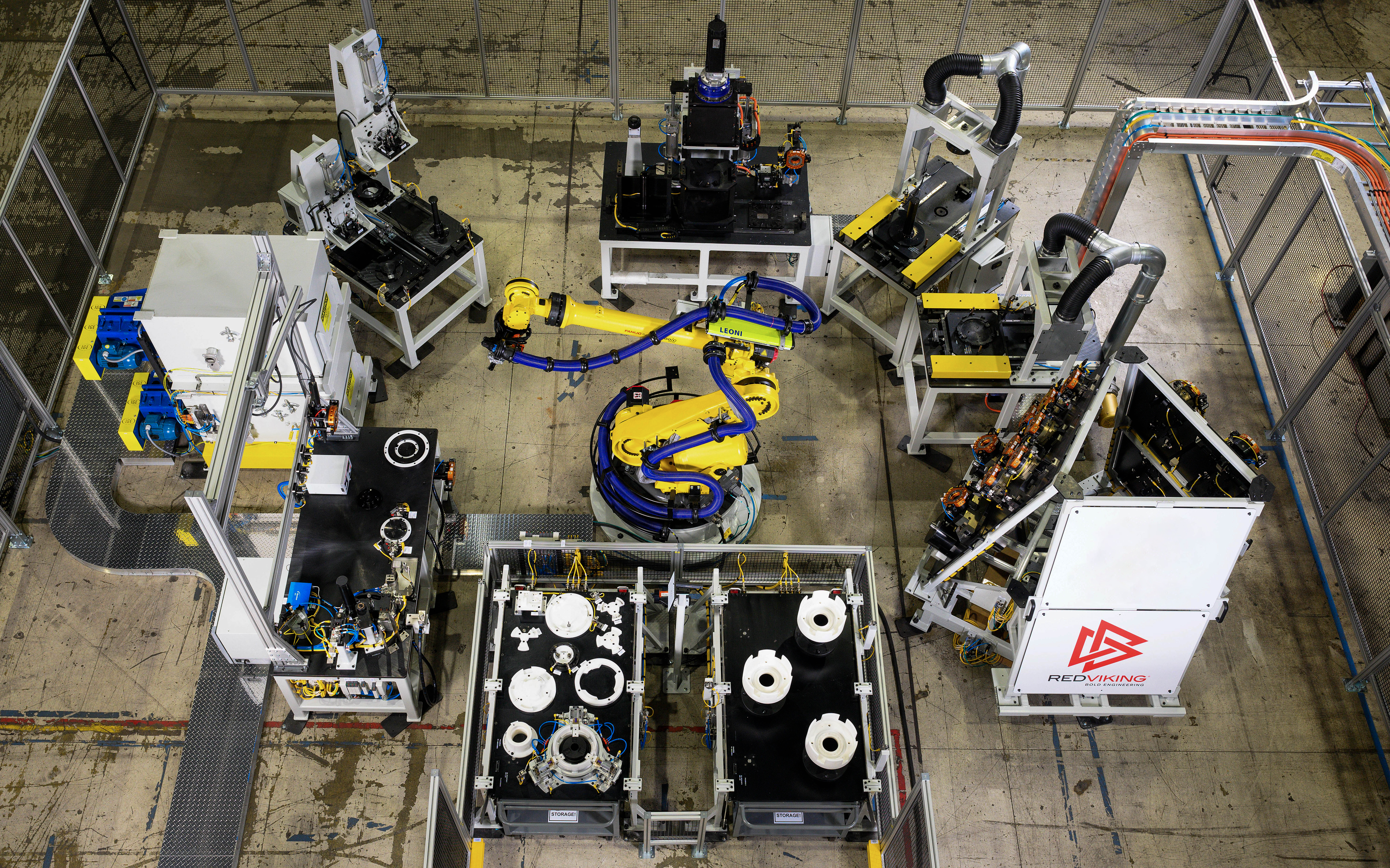

AGV Prove-out for Uneventful Installations

We do all the prove-out at RedViking, taking the installation risk away from our customers. This is a sharp contrast from most conveyance installations, where there’s no way to fully test the solution except on the customer’s plant floor. We prove out all of the mechanics and controls on our one-of-a-kind inductive power test track in Michigan. One customer thanked us for a “boring” first day back after installation, and another told us that their line had never started up so perfectly. The operators really appreciate being able to access the line from any side of the AGVs because it saves time. The solution is operating through all shifts without interruption. Want to learn more? Use our contact form or email us at engineering@redviking.com. Our phone number is +1.734.454.0500.