Another acronym to remember – Is it Terrific Dinner Party? Terrible Dance Partner? Totally Daft Person? Perhaps, but no.

It is Technical Documentation Package, the collection of information accompanying a machine or system for the end user to safely operate and maintain their investment. Depending on the project size and requirements, the TPD can vary greatly in scope. Some customers have exacting specifications for the documents that must be provided with their equipment while others have none. Some customers have templates or forms they will provide that must be completed and included as part of the TDP. Other customers rely solely on the machine or system OEM to determine what is included.

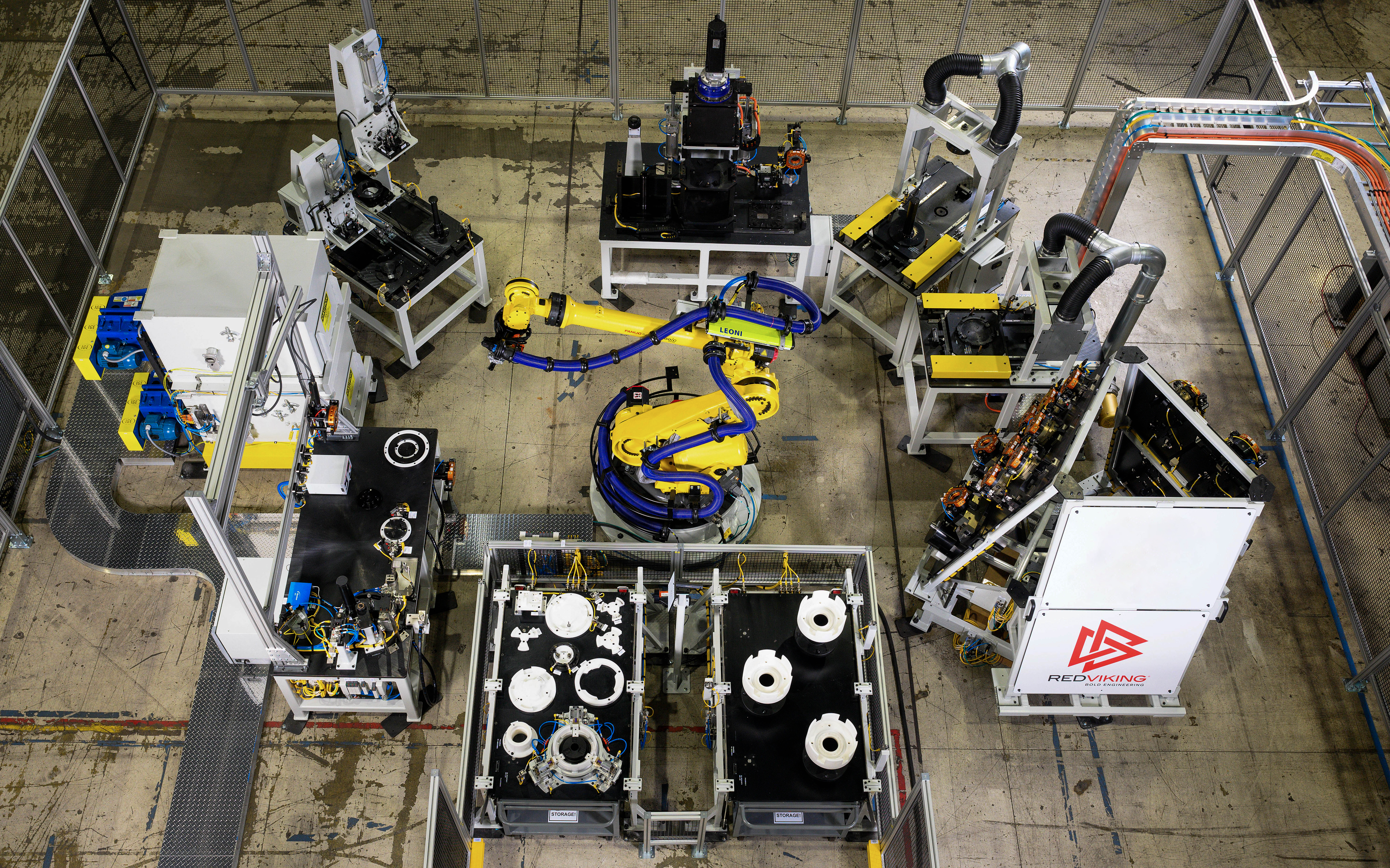

RedViking’s standard TDP includes an operation and maintenance manual, Tier II literature, spare parts lists, controls drawings, mechanical drawings, and safety lockout placards. Training material, visual job aids, and other program-specific documents may also be developed to enhance the TDP.

A test system featuring the RedViking Vsync test executive software includes its own set of documents. The TDP can be supplied in electronic or hard copy media or both. On machines or systems with computer-based control, an electronic copy of the TDP can be included on the computer interface.

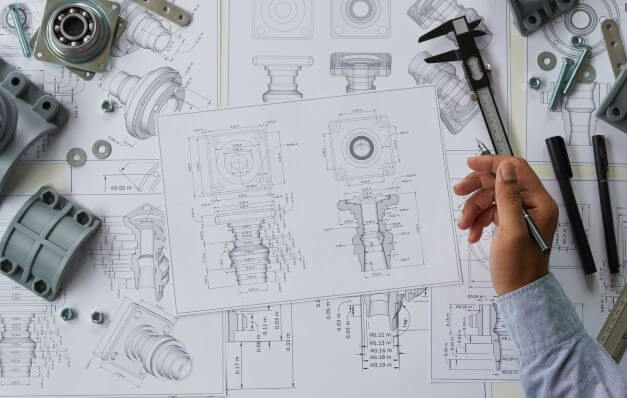

TDPs are developed by documentation specialists with an educational background and/or related work experience in the field. The documentation specialist compiles and consolidates information from a variety of sources such as customer SOWs, proposals, specifications, drawings, and other engineering documents. The documentation specialist then consults with RedViking’s subject matter experts, including electrical, mechanical and fluids engineers, machine builders and electricians and project managers, to verify content and then finalizes the TDP.

Regardless of the size and scope of the project, the TDP is an important component of a machine or system. It is used by the various personnel who are assigned to, or responsible for, running the system. Operators and other production personnel use the operating procedures for system start-up, shut-down, setup, and part loading/unloading tasks. Maintenance technicians rely on the various sub-system maintenance tables and part replacement instructions. Engineers refer to the verification, calibration and software documents to ensure their machine is producing quality products. RedViking is proud to provide this comprehensive resource to its customers.

Technical documentation has evolved over the years, from all-text content produced on a typewriter at the start of the industrial age to an on-line, graphic and video-intensive and sometimes interactive experience today. Whatever the method of delivery, the basic need for technical documentation has not changed. Technical documentation serves to provide people with an understanding of, connection to, and confidence in the technology they use to do a job or enhance their day-to-day lives. RedViking’s thorough and well developed TDP adds value to our machines/systems and helps our customers to be more successful from their technology investment.