This is an excerpt from an article in Automation World by Mark Sobkow, Vice President of Manufacturing Solutions.

By following these principles of flexible assembly line design, manufacturers can pursue lean manufacturing in their current operation while also building capabilities to maintain or add lean improvements in the future.

Lean manufacturing seeks to make clear what adds value by reducing everything else. Lean is clearly not a fixed-point objective; accelerating global market competition demands operational flexibility to achieve lean objectives. Here are five principles, applicable across every type of manufacturing, where flexibility can be added to an existing assembly line to eliminate waste and build quality into the system.

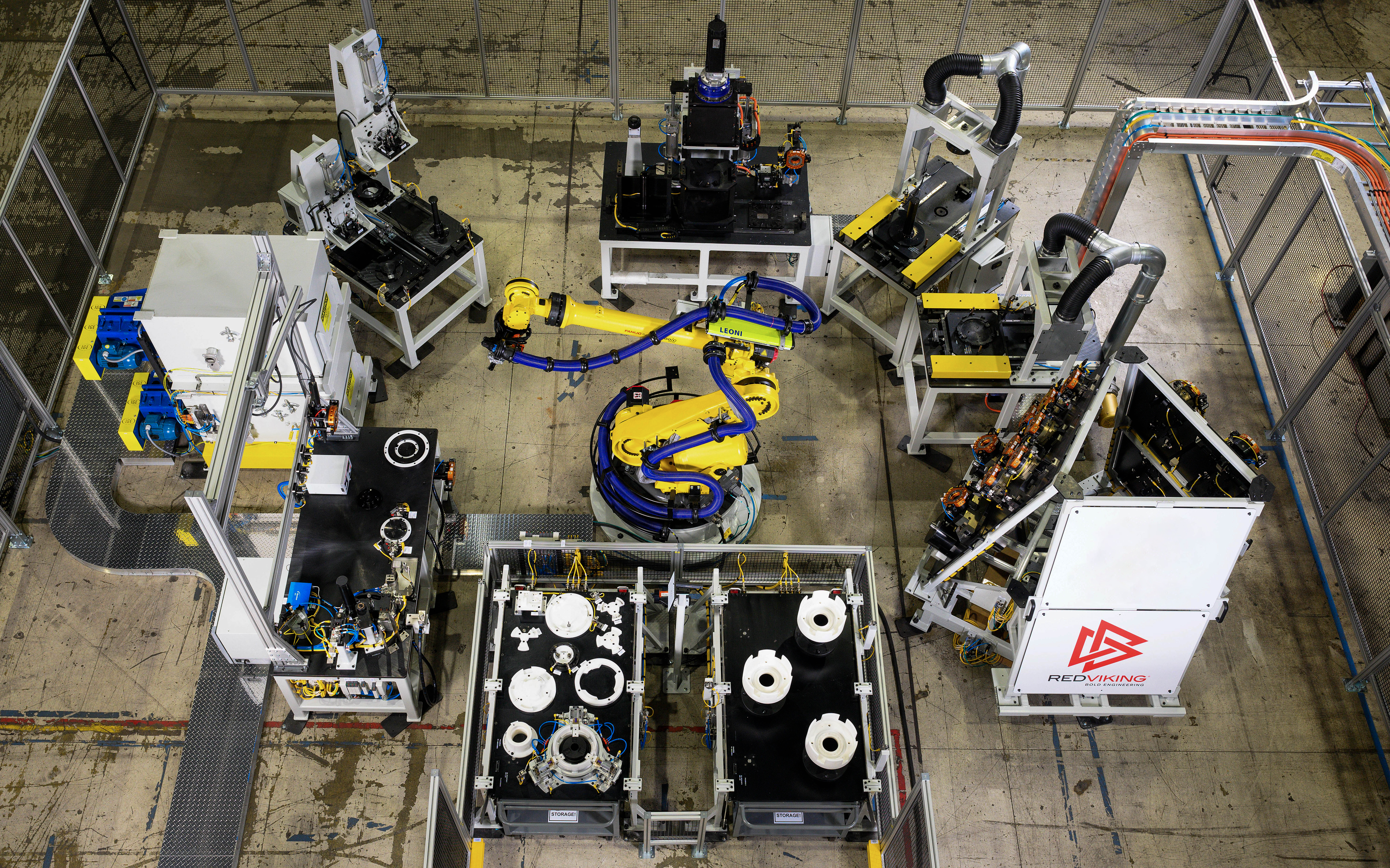

Consolidating machine functions and using docking station architecture are two great examples of how to make your machines do more. Automotive exhaust system producers have been extremely successful at effectively implementing docking station architecture. Where they once created a dimensional gage, a leak test machine and a weld station for every part, they have now isolated uniform functions such as the programmable logic controller (PLC) and barcode reader, and placed them on a dock. Wheeled fixture stations are created for unique parts and hooked to the docks with quick connects. Significant waste is eliminated by retaining the docks through multiple part and fixture modifications. Helicopter powertrains were tested on dynamic test stands built for each unique helicopter. Today, the industry is moving to flexible designs with interchangeable gearboxes and dynamic motor configurations. Wheeled fixtures for pre-dressed test articles are also eliminating waste and improving quality.

2. Design for the future

Though it’s not possible to accommodate all future production requirements, designing a flexible assembly line to accommodate future capability and adaptability will set you apart. A couple examples include an aircraft and a jet engine manufacturer. In the first example, an aircraft manufacturer was taking up to 70 hours to measure and cut doors and hatch covers. Rather than simply automate the cutting process, they instead chose to integrate a laser radar point cloud into a robotic cutting path. The current process takes less than 10 hours. Because they studied the process in its entirety, they now have future capability to precisely measure and cut doors for all future aircraft. In another case, a jet engine manufacturer needed to exponentially increase capacity. They began the process with an engineering study and simulation, which clearly identified potential bottlenecks and areas for functional consolidation. Again, their evaluation of the process as a whole has enabled them to create a plant operation that will be flexible for future engine designs.

3. Detach your factory from the facility

The separation of plant infrastructure from machines and data is crucial. Some factories have gone so far as to remove all plumbing. Automated guided vehicles (AGVs) are a staple of material handling, but their use in manufacturing has only recently accelerated due to changing technologies. AGVs are a way to improve assembly line flexibility, improve quality and eliminate waste. Even manufacturers of very heavy equipment are using inductively powered AGVs. Generally assumed to require full tear-out, AGVs can in fact be implemented incrementally.

By moving data acquisition and analysis onto mobile devices, operators and managers can respond more quickly to new plant information such as bottlenecks, starved stations and machine downtime.

By moving data acquisition and analysis onto mobile devices, operators and managers can respond more quickly to new plant information such as bottlenecks, starved stations and machine downtime. On the data acquisition side, barcode readers can be replaced with mobile devices to track part inventories. With mobile data analysis tools, managers can remotely identify and address production problems and dispatch service staff. For more information, read “3 Ways to Implement Mobile in Manufacturing.”

There are risks in customizing commercial off-the-shelf (COTS) software and choosing specialty controls. Avoid becoming the only customer of a particular software or controls implementation Plants often choose COTS manufacturing execution system (MES) software because of its functionality, but then modify it so heavily that their internal programmers become the only experts for their system. Plant improvement programs could then be constrained by programming resources. By choosing your MES based on widely accepted industry programs such as Oracle or SQL, plant operations gain access to a wide base of programmers. When controls are selected based on a unique application, the same risk exists. By choosing industry-standard controls, such as Siemens and Rockwell, a plant significantly expands its pool of controls engineers.

5. Don’t over-automate

Seek guidance on when to automate and when to retain manual processes. As system integrators, we look at every manufacturing problem as an opportunity for brilliantly engineered automation. At the same time, we understand that every piece of automation needs to earn its place on the line. This means that there are plenty of times when manual processes should be retained. Deciding when to automate or not? Ask yourself these five questions. By implementing these five principles of flexible assembly line design, manufacturers can pursue lean manufacturing in their current operation while also building capabilities to maintain or add lean improvements to future operations. Want to learn more? Use our contact form or email us at engineering@redviking.com. Our phone number is +1.734.454.0500.